Extending the Lifespan of Takahama Units 1 and 2: Sloppy RPV Surveillance Method

written by Hiromitsu INO

Nuclear Power Plant Ageing Problem Research Group,

Professor Emeritus of the University of Tokyo

On April 30, 2015, Kansai Electric Power Company (KEPCO) applied to the Nuclear Regulation Authority (NRA) for an extension of the operating limit of Units 1 and 2 of their Takahama Nuclear Power Station from 40 to 60 years.

In order to implement this operating limit extension, it is necessary to update the security regulations by performing meticulous inspections and formulating a maintenance and management policy document as well as receiving the necessary approvals and certifications, such as the “approval of alteration of reactor installation” in compliance with the new regulatory requirements. In all of this, one of the crucial points of controversy is the soundness of the reactor pressure vessel (RPV). Neutron irradiation causes embrittlement of the pressure vessel. The benchmark for irradiation embrittlement is the ductile-brittle transition temperature (DBTT), which rises as embrittlement proceeds. The difference in the temperature of the water injected at the time of a reactor accident and the temperature of the inner face of the RPV could cause the RPV to experience a fracture failure.

Surveillance specimens of steel materials made from the same material as the RPV are placed inside nuclear reactors and withdrawn occasionally to monitor the change in their DBTT, etc. The DBTT of the RPV itself is thus predicted, but is it possible to make correct predictions using this method? We asked Hiromitsu Ino, a professor of metallurgy and materials science, to explain for us the problems with the surveillance test method for structural materials of nuclear reactors and their relation to the soundness of the RVPs of Takahama Units 1 and 2.

In January 2015, NRA organized an Investigation Team on Technical Assessment of the Surveillance Method for Nuclear Reactor Structural Materials.1 The team’s mission was to prepare “…a technical assessment paper and draft document interpretation of the standards for the surveillance method [which should be] finalized by about March 2015,” indicating that the deliberations were expected to be cleared away in around three months. However, a variety of controversies arose and the debate continued into April and beyond. It is thought that the reason why there was little option but to engage in somewhat prudent deliberations was perhaps that this author’s claims had an impact on the team after reaching their ears due, among other things, to the meeting organized by CNIC in the Diet buildings as well as the House of Representatives Member Takashi Shinohara’s NRA hearing and written questions submitted to the NRA commissioners.

1. Technical specifications for power generating nuclear facilities start from those established by the three organizations, the Japan Society of Mechanical Engineers, the Atomic Energy Society of Japan, and the Japan Electric Association. The regulatory authorities endorse these after a technical assessment and put them into practice.

These deliberations bear a close relation to the 20-year lifespan extensions of aging nuclear reactors exceeding 40 years of operation. KEPCO filed its operation extension applications for Takahama Units 1 and 2 with NRA on April 30. The assessment of the soundness of the RPVs, a crucial item in the application, was influenced by the conclusion reached by the investigation team. These two units are aged reactors which began operation in 1974 and 1975. The DBTT of surveillance specimens placed within the Takahama-1 RPV had reached 99ºC when removed in 2009, becoming Japan’s worst by overtaking the 98ºC of Genkai-1.

Steel is ductile (capable of being bent or pulled into different shapes) at temperatures higher than a certain temperature, but becomes brittle at lower temperatures. There are numerous examples of accidents involving brittle failure, such as the sinking of the Titanic in 1914, hull fracture in large numbers of the American Liberty transport ships during the 2nd World War, and the rupture of the expressway girders in Kobe when the Great Hanshin-Awaji Earthquake struck in 1995. In the case of the Titanic, the post-accident investigation revealed that the ship had been built using poor quality steel with a DBTT of 27ºC.

RPV steel is progressively damaged by neutrons from the reactor core, resulting in a gradual increase in the DBTT. As this occurs, the pressure vessel becomes more susceptible to shocks. When considering an extension of operating lifespan, it is necessary to carry out investigations to ascertain that the steel plate of the pressure vessel is able to withstand the heat shock of rapid cooling in an emergency situation. That investigation requires a prediction of the DBTT of the steel, and this is carried out using the Japan Electric Association’s technical specification “Monitoring Test Method for Structural Materials of Nuclear Reactors JEAC4201-2007.”

The shift of DBTT by irradiation is indicated in the numerical tables of JEAC4201-2007 as a function of neutron fluence and flux, and the chemical concentrations of Cu and Ni in the RPV steel. The future predicted curve of DBTT is drawn by plotting the values from the table, and then adjusted so that the actual measured data from the surveillance specimens are included below the curve. The fracture toughness (a value indicating how much force imposed on the leading edge of a crack the material can withstand without fracturing) is calculated and a judgment made about whether or not the RPV can withstand a pressurized thermal shock. For this judgment, a separate regulation, the “Method of Confirmation of Fracture Toughness for Nuclear Reactor Power Generation Equipment: JEAC4206-2007” is used.

Technical standards developed by professional associations (the Japan Society of Mechanical Engineers, the Atomic Energy Society of Japan, and the Japan Electric Association) are subjected to evaluation by the regulatory agency, i.e. NRA, and then endorsed. The JEAC4201-2007 (2013 supplement) prepared by JEA is currently undergoing this process.

As it happens, at the time of the Nuclear and Industrial Safety Agency’s Hearing Committee on the Technical Assessment of Aging (November 2011 to August 2012) faults were found with this JEAC4201-2007. Not only could the DBTT of 98ºC of the Genkai-1 surveillance test not be predicted using this prediction formula, it was also pointed out by the present author, a member of the hearing committee, that there was a simple error in the reaction rate formula.2 As there were committee members at the hearing who claimed that there was no problem with the prediction formula in terms of engineering, the conclusion was held over and deliberations were ended, leaving the matter up to discussions between the relevant organizations.

2. In steel that has been irradiated by neutrons, impurities such as copper atoms become mobile due to atomic vacancies and form clusters. These clusters obstruct plastic deformation, causing the DBTT to rise by hardening the steel. The speed of movement of copper atoms is determined by what is known as the diffusion coefficient. The frequency of two copper atoms meeting (the reaction rate) is proportional to the second power of the number of copper atoms and first power of their speed of movement (the diffusion coefficient). Thinking about it for a moment, since both atoms move, it would seem that their frequency of meeting would be proportional to the second power of the diffusion coefficient, but this is not so. This is because of the notion of the random walk – the random movement of atoms. Being similar to the way drunkards walk, it is also sometimes known as the drunkard walk. Thus the frequency of the meeting of two atoms is determined as linearly proportional to the movement of one atom, since it makes no difference if one atom is moving or two atoms are. It appears that the authors at the Central Research Institute of Electrical Power Industry (CRIEPI), members of the specification committee at the Japan Electric Association, which devised the prediction formula, unwittingly made this elementary mistake. While they should have recognized the mistake and reconstructed the formula, perhaps fearing the consequences of recognizing the error, one of the authors, Mr. Naoki Soneda, aggressively stated at the hearing and elsewhere, “The second power does not stem from theoretical considerations… What I’m saying is that this model serves well to describe the process.”

The Japan Electric Association nevertheless accepted this admonishment, but with almost no substantive deliberations altered the parameters of the reaction rate formula, the basis of the prediction formula, to fit measured values in order to establish the 2013 supplemented edition of JEAC4201-2007. What the NRA Investigation Team on Technical Assessment of the Nuclear Reactor Structural Materials Surveillance Test Method presented as one of its items for consideration was the notion that “We evaluate the technical adequacy of the differences in the 2007 edition, which has already undergone technical assessment, … and the 2013 supplemented edition … and therefore the appropriateness of the prediction method is evaluated as providing adequate prediction results,” thereby blocking off any discussion on the 2007 edition itself.

Even under this restriction, two of the three external specialist members of the Investigation Team expressed critical opinions of the prediction method. These opinions included the following. “Determination of the coefficients of the reaction rate formula and so on when deriving the prediction formula indicated only the results and could not be checked by anyone except the persons actually involved. If this was a scientific paper, it would be rejected, and therefore the data and process of calculation should be disclosed in order to make it possible to verify the coefficients.” “Willy-nilly alteration of the coefficients each time data was added cannot be called a prediction formula, and is actually nothing more than a correlating equation. Isn’t it dangerous to make predictions that exceed the scope of observation of the data?”

At the third meeting, a “Draft Technical Evaluation of the 2013 supplemented edition of JEAC4201-2007” was presented by NRA and several important issues were discussed.

One of these issues was how to treat the discrepancy between measured values and predicted values. Measured values suffer from measurement errors, and these could be expressed statistically by standard deviation (indicated as MR in JEAC4201-2007), but it was also said that adding in a deviation (indicated as MC) for each plant would greatly improve predictions. However, the real nature of MC is not that it derives from data scattering, but is a bias arising from inadequacies in the prediction formula. Saying that adding in MC improves predictions is, in other words, the same as hinting that either there are errors in the prediction formula or that there are unknown factors that had not been considered. Clearly, a review is necessary.

The second issue is the grave problem of “whether or not this prediction formula can be used to make predictions.” The forceful opinion was put forward by one of the external specialists that a formula for which the formula coefficients change each time measured values are added is nothing more than a correlating equation and cannot be used for extrapolation. The NRA executive Masashi Hirano also stated that “(To extend the lifespan of a reactor from 40 years) we want to know the degree of irradiation embrittlement that corresponds to the fluence (amount of irradiation) in 20 years’ time.” To this, Mr. Aoki, head of the Technical Basis Department stated that “… it is not necessarily a condition that we have the data for 60 years at the 40-year point,” and thus opinions were split. What this means is that when deciding on the lifespan extension, even if the predicted value 20 years in the future cannot be known by interpolation, it is appropriate to take additional surveillance data during the extended period. The participants from the Japan Electric Association reacted strongly against all opinions (including those of NRA) to block off extrapolation.

Jointly with Prof. Masahiro Koiwa, this author submitted a written opinion to the Investigation Team chairman, NRA Commissioner Satoru Tanaka, demanding that cautious deliberations be conducted regarding the above matter.

At the fourth Investigation Team meeting held on 25 June, a technical assessment of the 2013 supplemented edition was presented by NRA and largely agreed upon. It was then decided to submit the technical assessment to NRA for the solicitation of public comments.

Since the draft technical assessment approved of the 2013 supplemented edition almost as it was, the content is far from being acceptable. There was, however, little option but to accept our claim that MC is a value representing a bias and not data scattering. Nonetheless, this was not clearly stated, and the half-hearted rhetoric of the assessment cautiously avoided criticism of the Japan Electric Association’s claims.

The most problematic aspect of all of this is that there is a pretence not to carry out extrapolation, as emphasized by the external specialists, but on condition of taking surveillance data during the extended period, embrittlement prediction of RVPs is to be also carried out for higher neutron fluences than those for which surveillance data exist at present.

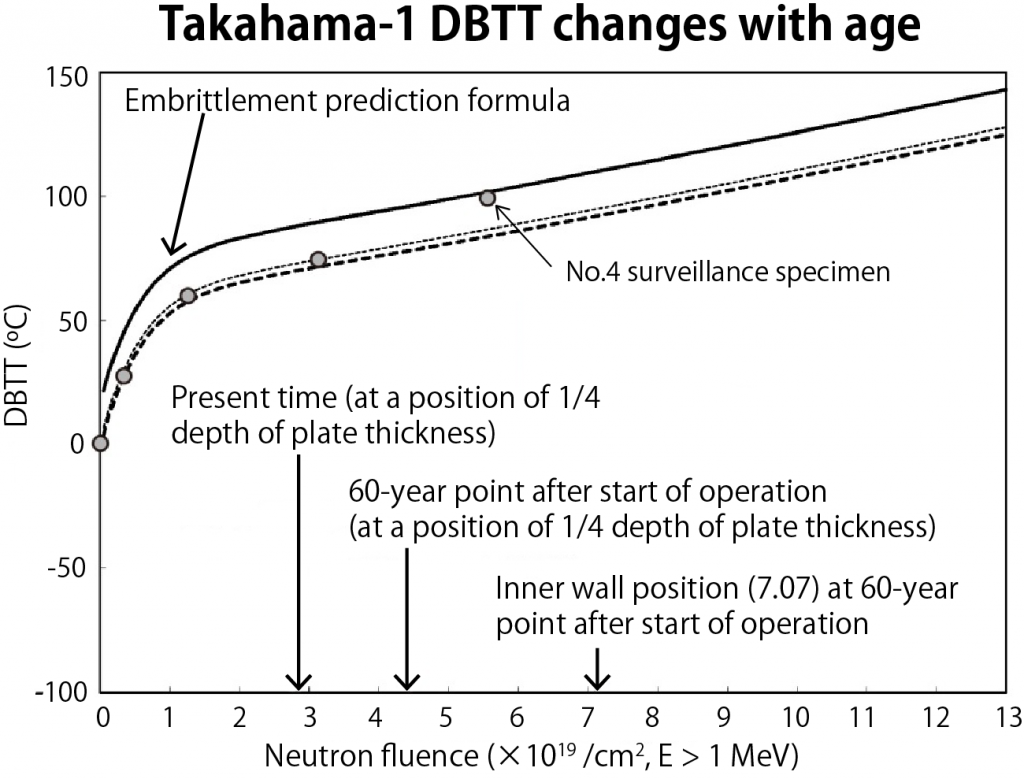

This now has a direct bearing on the reviews for Takahama Units 1 and 2, for which operating extension applications have been filed. The prediction data for Takahama Units 1 and 2 for 20 years in the future have not yet been derived. As the surveillance specimens inside the reactors are placed closer to the reactor core than the inner wall of the RPV, it is possible to “foresee” the future to some degree. However, as shown in Figure 1, since the data from the latest 4th surveillance specimen in Takahama-1 is the equivalent to a neutron fluence of 5.6 (×1019n/cm2), at the point in time 60 years from the start of operations (after a 20-year extension) the estimated fluence at the position of the inner wall of the RPV is expected to be lower than 7.07 (×1019n/cm2). In other words, DBTT cannot be estimated without extrapolation. There is no guarantee that things will turn out as shown by the prediction curve in the figure, and it rather looks from the trend of the data points more like the curve will shoot unfortunately upwards.

Figure 1. DBTT measured by monitoring tests at Takahama-1 (circles) and the embrittlement prediction curve based on the 2013 supplemented edition of JEAC4201-2007. Note that the 60-year position has been revised downward compared with previous reports.

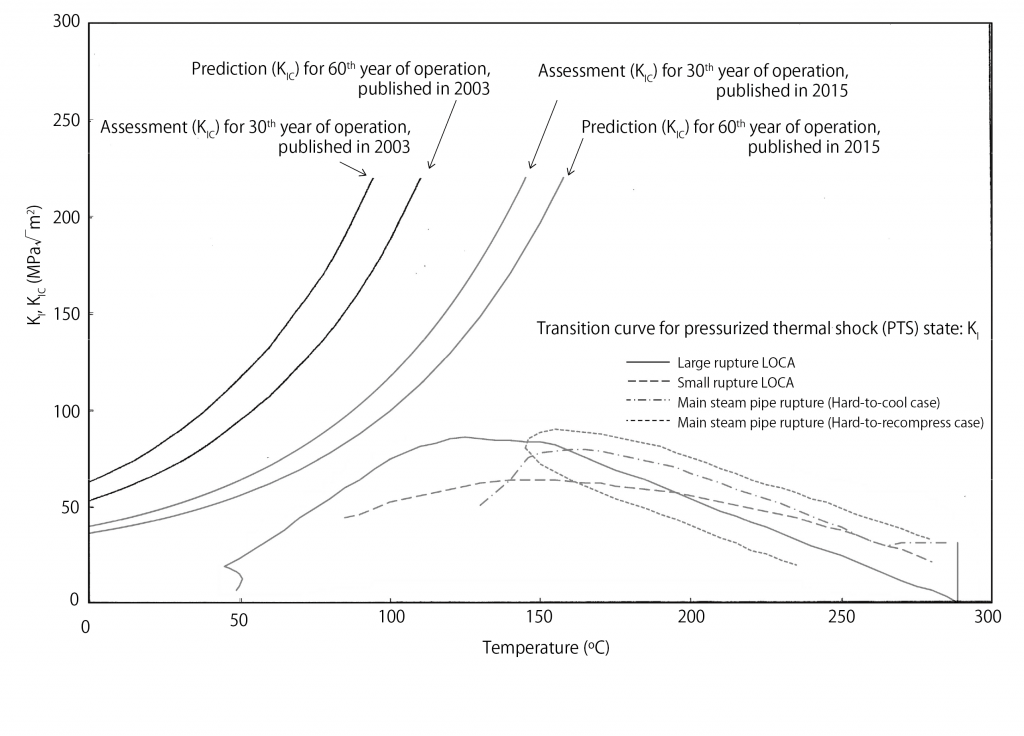

In 2003, KEPCO submitted an “Aging Technical Assessment Report (30th Year)”, and recently, in April 2015, KEPCO has submitted an “Aging Technical Assessment Report (40th Year)” in the request for a lifespan extension. What is surprising when comparing the fracture toughness assessment graph in both reports is that there is a huge difference in fracture toughness assessment at the point where the reactor has been operated up to 60 years (Figure 2). The 40th year assessment shows the fracture toughness curve at the 60-year point approaching the pressurized thermal shock (PTS) state transition curve. That there should appear such a great difference in the assessment for the same 60-year point is obvious visual proof of just how unreliable the fracture toughness curve assessment is. Since interception of the two curves means that the RVP will be in a state ready to crack open, the uncertainty surrounding the fracture toughness curve is truly frightening.

Figure 2. Takahama-1 pressurized thermal shock (PTS) assessment. Comparison of fracture toughness curves in the 30th year and 40th year Aging Technical Assessment Reports

The reasons why this difference has appeared are firstly that the DBTT rose beyond expectations compared with the 30th year assessment because the embrittlement prediction formula was revised upwards. Secondly, and this is an inference that is not backed up by published measured data, it seems likely that the fracture toughness of the fourth surveillance test showed embrittlement that was beyond expectations. Data disclosure and cautious deliberations are required.

The Japan Electric Association, consisting almost completely of nuclear power-related corporations and very few individual members, is, in fact, an industry organization. It is more exclusive than other organizations such as the Japan Atomic Energy Society. It would seem unreasonable to expect it to be capable of the “fairness, equitability and transparency important in a process to formulate specifications”. Specifications established by such an organization should not be adopted as technical standards. It is necessary to insert the scalpel into the fundamental policy of regulation that delegates the establishment of specifications to the three organizations, which form one wing of the promotion of nuclear power.