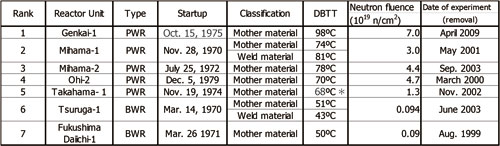

Genkai-1

is the worst. The DBTT for this reactor was announced in October 2010.

The figure comes from the most recent test of monitoring specimens in

April 2009. The DBTT rose 42°C since the previous test result of 56°C

in February 1993. This is a new record for Japan. This reactor will be

discussed in detail in NIT 149. All

the reactors listed from second to fifth place in the table are located

in Fukui Prefecture and are owned by Kansai Electric Power Company

(KEPCO). In particular, we have been concerned about the continued

operation of Mihama-1&2, where high DBTTs have been observed since

the beginning of the 1990s. KEPCO asserts that results of pressurized

thermal shock (PTS) analysis show that even if the ECCS was used in the

event of a pipe rupture the pressure vessel would not fail. However,

the evaluation methodology for the stress arising, KI, has not been released, so it is impossible to know whether this analysis is reliable. PTS

analysis assesses the pressurized thermal shock to the core of PWR

pressure vessels in the case of accidents such as loss of coolant

accidents and main steam pipe ruptures. It is necessary to confirm that

the critical stress intensity factor KI does not exceed the fracture toughness KIC. The reactors listed in sixth and seventh places in Table 1 are BWRs. The inner diameter of BWR pressure vessels is large compared to PWRs and the amount (flux) of neutron irradiation received in a given time is one or two orders of magnitude less than in PWRs. From the table it can be seen that the total amount (fluence) of irradiation received by Tsuruga-1 is about one thirtieth of that of Mihama-1, even though they began operating at much the same time. (There is a slight difference in operating time and also in the date the specimens were taken.) Consequently, it was thought that neutron radiation embrittlement was not such a big problem in BWRs as it was in PWRs. (Even now many researchers and engineers are still in the grips of that "common sense.") However, after many years of operation, as we came to know the reality of irradiation embrittlement in BWRs, this "common sense" has been overturned. The total amount (fluence) of irradiation is not the only determining factor for irradiation embrittlement. It has become clear that the rate (flux) at which irradiation occurs is also a determining factor. As will be discussed in part two, this led to an amendment to the monitoring specimen method JEAC-4201 and to the situation where two BWRs are now listed among the worst seven and other BWRs are also known to have high levels of irradiation. Why Does Irradiation Embrittlement Occur? - Basic Concept Metal

materials become degraded for all sorts of reasons. One reason is

"radiation damage." This phenomenon is investigated at the atomic level

though the study of lattice defects. The Physical Society of Japan has

had a section on lattice defects for over 50 years. As a personal note,

I have devoted myself to this field of research since becoming

interested in it as a university student. I became a tutor at Osaka

University and experienced the student uprisings of the 1960s. In

hindsight I can see that this field of research, which originated in

the United States, developed in tandem with nuclear energy.

Nevertheless, that fact did not lead me to abandon the field. I carried

out materials research using radiation as a guest researcher at the

Kyoto University Research Reactor Institute. However, it was difficult

to see a connection between this research and the social problems

associated with nuclear energy. The

reason why irradiation defects became an important research theme was

because when neutrons generated by nuclear fission hit reactor vessels

and pipes they damage the metal materials. This is called "neutron

radiation damage." If this causes materials to become brittle, it is

called "neutron irradiation embrittlement." Of particular importance is

neutron irradiation embrittlement of the steel of the reactor pressure

vessel, which is the heart of a nuclear power plant. If this is damaged

it can lead directly to a severe and uncontrollable accident. What

type of lattice defects arise from neutron radiation? In crystals,

atoms are precisely aligned in lattices, but if they are struck by a

neutron they are displaced, leaving a hole. This is called a "vacancy."

Displaced atoms are called "interstitial atoms." This phenomenon is

called a "lattice defect." In addition, secondary defects result when

vacancies and interstitial atoms move about and accumulate, creating

"vacancy clusters" and "interstitial atom clusters," respectively.

Impurities within the metal (copper atoms etc.) move to form "impurity

clusters." These "secondary lattice defects" cause metals to lose their

characteristic ductility (plasticity) and become brittle. To compare it

to the human body, it is like the hardening of the arteries which makes

blood vessels vulnerable to rupture. Usually,

when a force is applied to steel it simply deforms without breaking,

but below a given temperature, if the slightest force is applied,

rather than deforming plastically it shatters like pottery. This

critical temperature is called the ductile-brittle transition

temperature (DBTT). This brittleness of steel used to be the bane of

shipbuilders. Many ships sank due to this phenomenon. The Titanic,

which sank exactly 100 years ago in 1912 when it struck an iceberg

while crossing the North Atlantic Ocean, is a famous example.

Subsequent studies showed that poor quality steel plate was used and

that the DBTT was 27°C. When

reactor pressure vessels are bombarded by neutrons the DBTT rises. When

designing nuclear reactors it is necessary to predict how high the DBTT

will rise and whether they can survive for the period of their design

lives. However, assuming a design life for nuclear reactors of 40

years, it is impossible to know what condition they will be in after 40

years until the 40 years has actually elapsed. That presents a problem,

so accelerated experiments are conducted. Accelerated experiments are

tests that are commonly used to assess endurance by, for example,

applying forces beyond the normal load, or operating plants at greater

than normal speed. Likewise,

when conducting tests for neutron irradiation embrittlement, the amount

(flux) of neutron exposure in a given period of time is increased far

above normal amounts. Materials test reactors can radiate materials at

a rate of 1012n/cm2s (neutrons/square

centimeter). This rate (flux) of exposure is between 100 and 10,000

times the rate of exposure in normal reactors, given that the rate of

exposure for PWRs is 1010n/cm2s , while the rate for BWRs is 108n/cm2s

. That means the amount of irradiation a BWR would sustain in 40 years

can be applied in one or two days. Using such data a formula predicting

embrittlement was produced. Furthermore, besides the normal monitoring

specimens, accelerated monitoring specimens are also placed in BWR

reactor vessels. They are placed not on walls of the vessel itself, but

closer to the core, where the rate (flux) of radiation is an order of

magnitude higher. The idea is to predict the future state of the

reactor. Likewise, monitoring specimens are placed deeper inside PWRs

than the walls of the reactor vessel. For example, in the case of

Genkai-1, discussed in part two, the rate of radiation is about double

the normal rate. This is an attempt to read the future. Rise in DBTT = material factor x F(f) The

material factor is determined by the type and the concentration of

impurities in the steel. For example, if the steel contains a large

amount of copper, the material factor will rise. F(f) is the irradiation factor. It is postulated to be a function of the fluence of neutron irradiation "f" alone. With

accumulated experience of operating nuclear power plants, it became

possible to obtain long-term monitoring test data in real life

conditions, and it became clear that this formula was suspect. In

particular, with regard to BWRs, for which the rate of irradiation is

slower, it became clear that the results for the normal monitoring

specimens and the accelerated monitoring specimens placed in reactors

did not agree. This trend is particularly pronounced in reactors like

Tsuruga-1 and Fukushima Daiichi-1 where the steel of the reactor

pressure vessels contains large amounts of copper impurity. It can be

seen from this that the irradiation factor F(f) is dependent not only on the fluence (total amount) of neutron irradiation "f", but also on the flux (amount in a given time) of irradiation. We

noticed this over ten years ago and alerted researchers to the issue.

However, at the time, the results of American research refuting

dependence on the flux of irradiation held sway, so Japanese

researchers refused to take the matter seriously and did not alter the

embrittlement prediction formula. Faced with data from Tsuruga-1

showing unpredicted high levels of DBTT, METI's Aging Response Review

Committee dismissed the results saying they were due to data scatter. Thereafter,

analysis of the micro-formation of copper progressed, and it became

clear that when the rate of radiation is slow mainly clusters of copper

atoms (obstructions) form, whereas in accelerated irradiation tests

mainly clusters of vacancies form, so the cause of the hardening

(embrittlement) is different. The results of this micro-analysis backed

up our computer simulations. The outdated thinking described above was

forced to give way and now the dependence of radiation embrittlement on

the flux of irradiation is the shared academic understanding. The

irradiation embrittlement prediction formula used in monitoring test

methodology was changed and a new methodology (JEAC 4201-2007) was

produced*. Assessment of pressure

vessels shifted to the 2007 formula from mid-2011, but when the

increase of DBTT using this formula is smaller than that using the

previous 2004 formula, the 2004 formula is included as a reference. However, even the 2007 formula cannot explain the high DBTT for metal welds in Tsuruga-1 that we have drawn attention to. The metal welds in Tsuruga-1 have low levels of copper impurities, unlike the parent metal, and thus should not show a high DBTT. The amended JEAC-2007 was not adequately able to explain the complex nature of the reality of the metal materials. Unpredicted Embrittlement in Genkai-1 Reactor Pressure Vessel Further

"unpredicted" monitoring specimen data were observed; these were the

results from Genkai-1. At the October 25, 2010 meeting of Karatsu City

Municipal Assembly's Pluthermal Special Committee, Kyushu Electric

Power Company announced that the DBTT observed in Genkai-1's fourth

monitoring test specimen, taken during a periodic inspection in April

2009, had reached 98°C. Previously, the highest DBTT for a reactor

pressure vessel had been 81°C for metal taken from a weld at Mihama-1

(see Table 1). The Genkai-1 specimen exceeded this,

so it would be fair to conclude that Genkai-1 is the most dangerous

reactor pressure vessel in Japan.

It

is also very significant that this embrittlement was unpredicted. The

DBTT observed in the previous (third) monitoring test (February 1993)

was 56°C. That had increased by 42°C, which was contrary to the

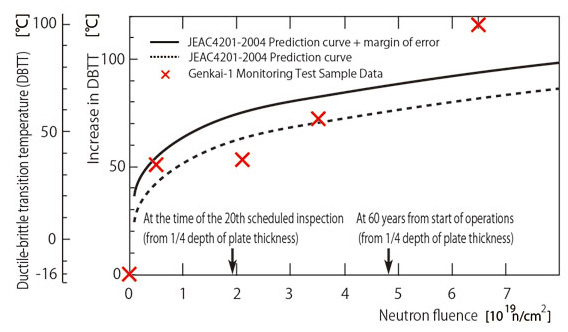

predicted result. Figure 1 is a diagram submitted by Kyushu Electric in its December 2003 Aging Technical Assessment, with a "×"

added to the top right corner to show the result of the fourth

monitoring test. Up until the third monitoring test the data points

could be more or less plotted onto the predicted curve, but the latest

data point is way above that curve. If you look closely at the diagram

you will see that the broken line is the predicted curve and that a

line is added above that showing the upper limit of the margin for

error. However, actual embrittlement is way above that upper limit. Kyushu Electric says that 98°C is the value predicted for 2060 (85 years after the start of operations), while the predicted DBTT for 2035 (60 years after the start of operations) is 91°C and for August 2010 (35 years after the start of operations) is 80°C. In part two, let us consider whether this is correct or not. (To be continued in the next issue of Nuke Info Tokyo) *Recently the author's group found that the formulation contains a fatal misunderstanding. Return to CNIC's Nuclear Saftey page Return to NIT 148 contents |

| CNIC Citizens' Nuclear Information Center Akebonobashi Co-op 2F-B, 8-5 Sumiyoshi-cho, Shinjuku-ku, Tokyo, 162-0065, Japan TEL.03-3357-3800 FAX.03-3357-3801 Map http://cnic.jp/english/ |