Kashiwazaki-Kariwa: Translation of Japanese Leaflet Nuke Info Tokyo No. 123

By Group of Concerned Scientists and Engineers Calling for the Closure of the Kashiwazaki-Kariwa Nuclear Power Plant

Contents

We demand that the Kashiwazaki-Kariwa Nuclear Power Plant be closed

Earthquakes and Ground Condition – Just how safe is the Kashiwazaki-Kariwa Nuclear Power Plant?

Is the equipment and machinery OK?

Column 1: TEPCO suppression of 34-year-old dispute about ground condition

Column 2: Materials get stronger when deformed by an earthquake!?

Column 3: Through the eyes of a power plant designer

The Group of Concerned Scientists and Engineers Calling for the Closure of the Kashiwazaki-Kariwa Nuclear Power Plant (KK Scientists) was formed shortly after the Chuetsu-oki earthquake*1. It was started by four people who, on 21 August 2007, issued an appeal. To date over 200 scientists and engineers have endorsed this appeal. They are actively demanding that objective scientific and technical investigations be carried out “keeping in mind the possibility of permanent closure of the plant”.

The Nuclear and Industrial Safety Agency (NISA) of the Ministry of Economy, Trade and Industry (METI) has established the “Subcommittee for Investigation and Response to the Nuclear Facilities affected by Chuetsu-oki earthquake”, chaired by Haruki Madarame, a professor of Tokyo University, and ordered Tokyo Electric Power Company (TEPCO) to check equipment and carry out seismic response analysis. However, these investigations are clearly being carried out based on the premise that the plant will be restarted in the near future. It would therefore be difficult to call them objective scientific and technical investigations. In addition, the nuclear industry is trying to lend authority to these investigations being carried out by the government and TEPCO by holding an international symposium in February this year in Kashiwazaki City*2.

As scientists and engineers, we believe that it is necessary to condemn and highlight the problems of this type of biased investigation, which is being carried out by the regulatory authorities and TEPCO without the participation of residents. We have prepared this document for this purpose and welcome comments on its contents.

Our key arguments are as follows:

- Kashiwazaki-Kariwa was never a place to build a nuclear power plant.

- Sloppy safety examination overlooked an over 40 km-long submarine active fault.

- This time was a miraculously lucky escape.

- The danger of another large earthquake remains. The government is violating its own seismic design rules.

- Important safety equipment may have been seriously damaged.

- TEPCO’s equipment checks are not capable of identifying all the damage.

- TEPCO’s seismic response analysis fails to identify the true situation.

- Struck by the double blow of aging and an earthquake, Kashiwazaki-Kariwa should not be restarted.

Footnotes

*1. The Chuetsu-oki earthquake (magnitude 6.8) occurred at 10:13 am on July 16 just off the coast of Niigata Prefecture on the Japan Sea side of Honshu, Japan’s largest island. As a result of the quake, four reactors (units 2, 3, 4 & 7) at Tokyo Electric Power Company’s (TEPCO) Kashiwazaki-Kariwa Nuclear Power Plant shut down automatically. At the time, unit 2 was being started up after a periodic inspection, while the other three units (1, 5 & 6) were still shut down for periodic inspection.

*2. The International Symposium on Seismic Safety of Nuclear Power Plants and Lessons Learned from the Niigataken Chuestu-oki earthquake was held in Kashiwazaki City on 26-27 February 2008.

Group of Concerned Scientists and Engineers Calling for the Closure of the Kashiwazaki-Kariwa Nuclear Power Plant

Toda Building 4F, Yotsuya 1-21, Shinjuku-ku, Tokyo, Japan, 160-0004

Phone and Fax: 81-3-3358-7064

kkheisa.blog117.fc2.com/

By Katsuhiko Ishibashi and Mitsuhisa Watanabe

Kashiwazaki-Kariwa was never a place to build a nuclear power plant

The Kashiwazaki-Kariwa area in Niigata Prefecture is located in the middle of an earthquake belt that stretches from the Japan Sea coast in the Tohoku district to the north through to the Shinshu and Hokuriku regions in the Chubu district to the southwest. It was known before the planning of the nuclear power plant that Niigata Prefecture had undergone many magnitude (so-called Richter scale) 7-class destructive earthquakes. Major quakes since the 16th century occurred in 1502, 1666, 1670, 1751, 1762, 1802, 1828, 1847 and 1964. Furthermore, this area is right in an active fold*1 region known as the U-etsu Fold Zone, and has many active faults each of which is evidence of repeated large earthquakes in the last several hundreds of thousand years. Thus ample reason existed to assume a risk of a major earthquake in the Kashiwazaki area.

It was known all along that the ground condition of the Kashiwazaki-Kariwa site was the worst among all of Japan’s nuclear power plants. It was necessary to dig down about 40 meters to get the supporting stratum for a nuclear reactor. Even then, the stratum is geologically too young and could never be called hard bedrock.

In a word, the Kashiwazaki-Kariwa area was never a place where a nuclear power station should have been built from the viewpoint of seismic safety.

But in 1977, ignoring a warning from a specialist in active faults, who was a member of the examination committee*2, and the regulatory guide for reviewing siting adequacy*3, the government approved the installation of the No. 1 unit of the Kashiwazaki-Kariwa power plant. Subsequently, as we will see below, choosing to overlook the presence of huge submarine active faults nearby, approval was given for six more units. This can only be viewed as suicidal ignorance and disregard of the forces of earthquakes as natural phenomena, as was starkly revealed by the 2007 Niigata Prefecture Chuetsu-oki earthquake.

Sloppy safety examination overlooked an over 40 km-long submarine active fault

|

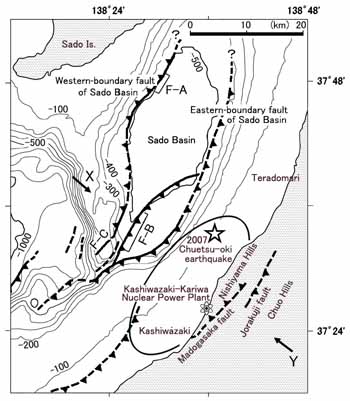

| Fig. 1 Major active faults in the vicinity of the Kashiwazaki-Kariwa Nuclear Power Plant The star shows the epicenter of the 2007 Chuetsu-oki earthquake. (Underground rupture along the seismic fault plane began directly beneath this point.) Slip on the fault plane spread to almost the whole area where aftershocks occurred (ellipse). Thick lines show active faults. (Broken lines are inferred ones.) Black triangles on the lines show dip-directions of the faults. The sea area is based on Watanabe et al.*4. F-A, F-B and F-C are faults after TEPCO’s application for a license variation for Units 6&7. The Madogasaka fault is after Watanabe et al.*4. The Jorakuji fault is after Nihon no Katsudanso (New Edition) (Research Group for Active Faults of Japan Ed., University of Tokyo Press, 1991). X-Y indicates the line of cross section shown in Fig. 2. |

In the safety examination of reactors No. 6 and 7, which were licensed in 1991, both the government and TEPCO claimed that there was no submarine active fault in the area to threaten the plant’s safety. They acknowledged the presence of the 7-8 km long F-B fault, as shown in Fig. 1, but stated that it was not an active fault. However, when Watanabe et al.*4examined the records of seismic profiling included in TEPCO’s application for reactor establishment after the 2007 Chuetsu-oki earthquake, it was easy to identify many such large-scale submarine active faults, as shown in Fig. 1. There are four main ones, three of which run along either edge of the Sado Basin, a depression between Sado Island and mainland Kashiwazaki.

In June 2003 TEPCO made a report to the Nuclear and Industrial Safety Agency revising their estimate of the F-B fault as a 20 km-long active fault. However, neither side made this new estimate public. Only finally in December 2007, after the Chuetsu-oki earthquake, was it publicly announced to be an active fault 23 km in length.

TEPCO stressed that this was “recent information” and wasn’t known at the time of the license application. However, this is utterly incorrect. Watanabe et al.*4 checked the data that TEPCO obtained and interpreted in its original application and, on the basis of criteria which were already authorized back in 1980, they were easily able to establish the existence of active faults at that location.*5 TEPCO’s evaluation of active faults is mistaken as to both position and length. In fact, the most important submarine active fault is not the F-B fault, but the Eastern-boundary fault of Sado Basin*6 shown in Fig. 1. This is over 40 km long, and capable of generating a major earthquake of magnitude 7.3~7.7.*5

Thus, TEPCO’s study and the government’s review of active faults in the offshore area of Kashiwazaki-Kariwa power plant is very slipshod, and it is obvious that they made a most peculiar evaluation of this crucial matter of active faults.

A major earthquake of magnitude 7 or greater could and should have been anticipated at the application and examination stage, and it must be a matter of grave concern that both TEPCO and the government “didn’t realize” this. They are refusing to admit their responsibility, and are bent on starting up production at the plant again as soon as possible, though they say they are carrying out a new investigation. Given this attitude, the same thing or worse could happen again.

|

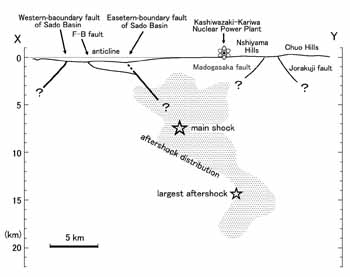

| Fig. 2: Schematic vertical cross-section along the line X-Y in Fig. 1 showing geomorphological interpretation. Looking from the southwest, based on Watanabe et al.*6. The shaded area shows roughly where aftershocks occurred in the region shown in this cross section. This area, as well as the location of the main shock and the largest aftershock, are based on results published by the National Research Institute for Earth Science and Disaster Prevention (www.hinet.bosai.go.jp/topics/niigata070716/). This figure is a rough sketch, because it is presumed that the seismic fault plane is warped and the topography is not absolutely perpendicular to this cross section. |

The recent Chuetsu-oki earthquake is thought to have resulted from underground rupture on the fault plane southeasterly-dipping from the Eastern-boundary fault of Sado Basin in which the land-side block thrust up northwestward over the sea-side block (Fig. 2). It is possible that the slight displacements on the Madogasaka fault adjacent to the power plant and the southern extension of the Jorakuji fault to the east caused the uplift of the Nishiyama Hills and the Chuo Hills. There was, in short, a sudden outbreak of crustal movement centered around the nuclear reactor area.

Repeated major earthquakes of this type appear to have formed the general topographic features in this area both on the sea bottom and on land. The 2007 Chuetsu-oki earthquake, however, was of smaller scale than is anticipated from the Eastern-boundary fault of Sado Basin, and there was not a great deal of alteration in growth of relief on this occasion; that is, it was an aborted quake for this area. The region can count itself lucky that this time what was in store for it did not eventuate. A quake of around magnitude 7.5 could easily have occurred, but thanks to the whims of nature the quake only reached 6.8.*7

The Chuetsu-oki earthquake struck the Kashiwazaki-Kariwa Nuclear Power Plant with violent ground motion far beyond that of the basis of seismic design. The plant suffered considerable damage, and there was radiation leakage. However, the three reactors that were in active operation and the one reactor that was being started up at the time scrammed and a major disaster was avoided. Some take this to be proof that nuclear reactors are safe and earthquake-proof. But this is surely a case of culpable optimism.

Thanks to a happy combination of chance and circumstance, this recent case miraculously let us off the hook, but it could well have been a very different story. If the earthquake had been of magnitude larger than 7 (instead of 6.8), or had there been a large aftershock immediately following, or had all seven of the reactors been in operation at the time, we might instead have been faced with a fatal accident in which massive amounts of radioactive material were released, making uninhabitable not only the Kashiwazaki and Kariwa environs but a wide area of Niigata Prefecture.

Danger of another large earthquake remains – Government is violating its own rules

The 2007 earthquake was preceded by one in the same region in 2004, pointing to a build-up of seismic energy in the area. Both were relatively small, magnitude 6.8, and there are many active faults both in the seabed and on land, so it is impossible to dismiss the likelihood of further major earthquakes. The next severe quake may be caused by major slip on the Madogasaka fault, for example, which may have perhaps undergone slight movement in the recent quake. It is also impossible to rule out a late aftershock of magnitude 6.5 or so occurring some years down the track directly under or in the immediate vicinity of the nuclear power plant. The possibility that this plant will be restarted is of grave concern indeed, given the extreme seismic hazard of the site, and the high possibility that it still carries considerable undetected damage from the recent quake.

In the 2006 revised version of the government’s Regulatory Guide for Reviewing Seismic Design of Nuclear Power Reactor Facilities the fundamental guideline states that “(all) buildings and structures shall be settled on the grounds which have sufficient supporting capacity”. The ground of the Kashiwazaki-Kariwa plant was deformed remarkably by the Chuetsu-oki earthquake, affecting and in many cases causing considerable damage to structures right across the plant site. It has already given ample proof that it does not have sufficient supporting capacity. Therefore, the plant is in clear violation of the fundamental guideline stated above.*8 Even by the standards of the nuclear power industry itself, the Kashiwazaki-Kariwa Nuclear Power Plant must not be allowed to continue to operate.

Footnotes

*1. Presently ongoing fold – a very slow wave-shaped distortion of strata during geological time span, mainly under lateral compression, where buried faults, which could potentially be the origin of earthquakes, often exist.

*2. See Niigata Nippo: Tsunen Kikaku (“Kashiwazaki-Kariwa Genpatsu – the Shaky Safety Myth”, 4.1, www.niigata-nippo.co.jp/rensai/n78/n78h5klml.html.

*3. The Regulatory Guide for Reviewing Siting of Nuclear Power Reactors (decided in 1964 – the basis of the scheme of regulatory guides for licensing review of nuclear facilities) states that the first principle for siting a reactor is that “there should be not only no event in the past such as would cause a large-scale accident, but no possibility of any such occurring in the future. Furthermore, there should be a minimum of factors likely to exacerbate the extent of any disaster.”

*4. Watanabe Mitsuhisa, Suzuki Yasuhiro, Nakata Takashi: Programme and Abstracts, Japan Association for Quaternary Research, No. 37, Suppl., 4(2007).

*5. Suzuki Yasuhiro, Nakata Takashi, Watanabe Mitsuhisa: Kagaku, 78, No.1, 97 (2008).

*6. This fault has been named by Watanabe Mitsuhisa, Nakata Takashi, Suzuki Yasuhiro: J. Geol. Soc. Japan, 114, 2008 (forthcoming).

*7. The seismic wave energy of a magnitude 6.8 earthquake is a little under 10% (i.e. less than one tenth) of that of a magnitude 7.5 quake.

*8. It should be added that this plant was in violation even of the earlier guidelines, which stated that “important buildings and structures should be on hard bedrock”.

By Hiromitsu Ino and Mitsuhiko Tanaka

Important safety equipment may have been seriously damaged

All of Japan’s nuclear power plants were designed under earthquake guidelines which have since been superceded*1. The Kashiwazaki-Kariwa nuclear power plant was designed for basic horizontal earthquake ground motions of 300 Gal*2 (S1) and 450 Gal (S2). These figures apply to a hypothetical surface called “free surface of the base stratum”*3, where S1 is an earthquake ground motion that could actually occur, while S2 is an almost inconceivable hypothetical earthquake ground motion. However, during the Chuetsu-oki earthquake, a seismometer*4 set deep underground in the Unit 1 site recorded a horizontal acceleration as large as 993 Gal. This figure cannot be directly compared with the abovementioned 300 Gal and 450 Gal readings. In order to compare the figures, it is necessary to carry out a “strip off inversion analysis”.*5 However, if this analysis were carried out the 993 Gal figure would be expected to rise even higher. This demonstrates that the Kashiwazaki-Kariwa nuclear power plant was struck by a massive ground motion that far exceeded the basic S1 and S2 earthquake ground motions assumed when the plant was designed.

Under the old guidelines, for standard earthquake ground motion S1, it was a legal requirement that key equipment and structural components of nuclear power plants be designed so as not to exceed the bounds of “elastic deformation”*6. However, for standard earthquake ground motion S2 they are allowed to cross the boundary of “elastic deformation” to a certain extent. That is to say, a certain amount of “plastic deformation”*7 is permitted. Because it is almost inconceivable that an S2 earthquake ground motion will actually occur during the life of the plant, a certain amount of permanent deformation is acceptable, even of key equipment and structural components, “as long as they don’t break”*8. This very dangerous concept was adopted, because cost was prioritized over safety.

To recapitulate, during the Chuetsu-oki earthquake, the Kashiwazaki-Kariwa nuclear power plant was struck by a massive earthquake ground motion that far exceeded both S1 and S2. Something occurred which was unprecedented in the history of nuclear power. A huge stress was exerted on key equipment and structural components that directly affect the safety of the plant: the reactor pressure vessel, nozzles, reactor internal structural components, support skirts, major pipes (e.g. main feedwater pipes, main steam pipes, recirculation pipes), the primary containment vessel, all kinds of pumps, turbines, and so on. We are concerned that metal materials may have suffered serious damage. Even if there were no visible changes to the structure and dimensions, it is possible that microscopic internal, potentially dangerous defects arose within the metal materials. As long as there is a possibility that important equipment and structural components have suffered this type of undetectable damage, we maintain that the Kashiwazaki-Kariwa Nuclear Power Plant is dangerous and should be closed down.

To recapitulate, during the Chuetsu-oki earthquake, the Kashiwazaki-Kariwa nuclear power plant was struck by a massive earthquake ground motion that far exceeded both S1 and S2. Something occurred which was unprecedented in the history of nuclear power. A huge stress was exerted on key equipment and structural components that directly affect the safety of the plant: the reactor pressure vessel, nozzles, reactor internal structural components, support skirts, major pipes (e.g. main feedwater pipes, main steam pipes, recirculation pipes), the primary containment vessel, all kinds of pumps, turbines, and so on. We are concerned that metal materials may have suffered serious damage. Even if there were no visible changes to the structure and dimensions, it is possible that microscopic internal, potentially dangerous defects arose within the metal materials. As long as there is a possibility that important equipment and structural components have suffered this type of undetectable damage, we maintain that the Kashiwazaki-Kariwa Nuclear Power Plant is dangerous and should be closed down.

TEPCO’s equipment checks not capable of identifying all the damage

Under the auspices of Nuclear and Industrial Safety Agency’s (NISA) “Subcommittee for Investigation and Response to the Nuclear Facilities affected by Chuetsu-oki earthquake”, a working group was established to assess management and control and the integrity of equipment (Chairperson, Naoto Sekimura, Professor of Tokyo University). The working group is trying to assess whether or not equipment was damaged by the earthquake. The assessment involves “equipment checks” and “calculation-based analysis”. However, in reality this is being done by TEPCO and the working group just discusses the results.

What sort of checks is TEPCO doing? First, it is doing “visual checks”. These can only reveal large flaws and distortions. Next it is carrying out “non-destructive tests” on sections which it judges to be suspicious. These involve looking for flaws using ultrasonic waves, or by permeating the section with liquid. These tests can only reveal the larger cracks. It is very difficult to find small flaws and it is completely impossible to find local distortion (plastic deformation) of the material and hardening before cracks form. As explained in the previous section, even if there are no detectable changes to the structure and dimensions, it is impossible to deny that internal microscopic flaws could have formed in the metal material. Furthermore, there are practical difficulties with the work environment. It is extremely difficult to find tiny flaws in huge structures such as the primary containment vessel. It is also likely that some parts which were subjected to great stress during the earthquake are very difficult to access and that sufficient testing cannot be carried out on these parts. Also, it is no easy matter to conduct tests in the highly radioactive environment around the reactor.

TEPCO’s seismic response analysis fails to identify the true situation

TEPCO relies on “seismic response analysis” (analysis of structural strength). NISA has indicated its basic policy on this to TEPCO and TEPCO has begun preliminary analysis. In regard to equipment and structural components which are important for the safety of the plant, NISA regards the issue of whether or not “elastic deformation” has been exceeded (i.e. whether or not plastic deformation has occurred) as a key distinction in the assessment of the integrity of equipment.

However, there is a big problem in this. Under NISA’s basic policy, the integrity of equipment is deemed to be confirmed as long as no flaws are found and the results of the analysis indicate that elasticity was maintained (i.e. that plastic deformation did not occur). But, as we have explained, the tests being conducted are incapable of discovering plastic deformation (local distortion), so even if the results of the analysis indicate elastic deformation, it is still possible that plastic deformation has occurred. Since this possibility is ignored, any declaration that the integrity of the equipment has been maintained would be based on an unconditional acceptance that an unverifiable theoretical analysis was correct. Hence, it is impossible to escape the conclusion that the assessment methodology is unscientific.

There are also problems with the methodology of the analysis itself. According to the analysis steps published by TEPCO, first a simplified calculation is conducted. If the results of this calculation indicate plastic deformation, an analysis equivalent to that used when the plant was designed is carried out. If plastic deformation is still indicated, a detailed assessment of whether plastic deformation has occurred is carried out, varying the damping constant*9 and amending the calculation model. If the results of this detailed assessment still indicate plastic deformation, they will confirm whether the equipment is capable of carrying out its function. In other words, if three stages of the assessment all indicate plastic deformation, theoretical analysis will be abandoned and the equipment will be given a rubber stamp of approval as long as it can still carry out its function. If this is their attitude, one wonders why they bother with the theoretical analysis in the first place. One can only conclude that they intend to derive the assessment result that the integrity of the equipment has been maintained no matter what, so that they can restart the plant. Their attitude is a far cry from our demand that “objective scientific and technical investigations” be carried out “keeping in mind the possibility of permanent closure of the plant.”

We demand that TEPCO publish not only the numerical results of its seismic response analysis, but that it publish its results in such a way that the whole analytical process can be reproduced. We also demand that NISA independently crosscheck TEPCO’s analysis and that it publish the whole process.

Struck by the double blow of aging and an earthquake, Kashiwazaki-Kariwa should not be restarted

The Kashiwazaki-Kariwa nuclear power plant is not new. Unit 1 began operations 22 years ago. Unit 7, the newest reactor, commenced operations 10 years ago. During that time the equipment has aged.*10 TEPCO’s seismic response analysis assumes that the equipment and machinery are new. But what if tiny cracks, not visible to the naked eye, have arisen as a result of aging? After the body blow from aging, along comes this huge punch from an earthquake. Considering the circumstances, a fundamental assessment of the integrity of the plant is necessary.

As an experiment, what about decommissioning and disassembling Unit 1 – which, being the oldest reactor, has aged most – taking samples and conducting metallographical tests and fracture tests, carrying out the latest instrumental analysis, and undertaking a fundamental and thorough assessment of the integrity of the plant? This would also be an extremely useful exercise from the point of view of research into the effects of earthquakes on nuclear power plants.

In a small country like Japan, a single nuclear accident would be enough to make a large part of the country uninhabitable for generations. On top of this risk, Japan is also one of the most earthquake-prone countries in the world. Not only would the scale of the destruction for Japan would be orders of magnitude greater than for larger countries, there is also the continual risk of an earthquake. To attempt to restart the Kashiwazaki-Kariwa nuclear power plant under these circumstances, without even fully confirming that it is safe, is a violation of corporate and professional ethics.

In a small country like Japan, a single nuclear accident would be enough to make a large part of the country uninhabitable for generations. On top of this risk, Japan is also one of the most earthquake-prone countries in the world. Not only would the scale of the destruction for Japan would be orders of magnitude greater than for larger countries, there is also the continual risk of an earthquake. To attempt to restart the Kashiwazaki-Kariwa nuclear power plant under these circumstances, without even fully confirming that it is safe, is a violation of corporate and professional ethics.

Footnotes

*1. The current guidelines were approved in September 2006, but so far no plants have been designed based on these new guidelines.

*2. Gal is a unit of acceleration. Gravitational acceleration at the earth’s surface is 980 Gal.

*3. Tertiary layers, or earlier bedrock that has not been eroded are generally referred to as “ground”. Hypothesizing that above this ground there are no layers or structures, the surface spreading out horizontally is called the “free surface of the base stratum”.

*4. Seismometer located 250 meters below sea level under reactor number 1.

*5. Method of deriving the hypothetical seismograph for the surface in question by analytically removing all superimposed layers and considering the layer in question to be an exposed surface.

*6. As with the deformation caused by pulling a rubber band, there is a proportional relationship between the force applied and the extension, and when the force is released the material returns to the same length and shape that it was before.

*7. With plastic change, after the force is released most of the change (distortion) remains permanently.

*8. Expression used on page 208 of the following practical design handbook: Takashi Hayashi, “Structural Design of Nuclear Power Plants” (Nikkan Kogyo Shimbun “Business Line”, 1984)

*9. See footnote 7 in Column 3.

*10. Items being considered by a committee established within the Ministry of Economy, Trade and Industry (METI) to investigate aging management for nuclear power plants include embrittlement of reactor pressure vessels due to neutron irradiation, stress corrosion cracking (SCC) of pipes, and metal fatigue. In 2002, when it was revealed that TEPCO had concealed cracks, SCC in the stainless steel of shrouds and recirculation pumps in the Kashiwazaki-Kariwa power plant were revealed and all 7 units were shut down. Since then no fundamental solution to the problem of SCC has been found and cracks continue to appear.

By a member of KK Scientists

TEPCO suppression of 34-year-old dispute about ground condition

Since as far back as 1974, the local anti-nuclear movement has been making the following claims. “Kashiwazaki-Kariwa was an oil field. It has active folds and active faults and is therefore unsuitable for a nuclear power plant. TEPCO’s survey for the construction of the plant ignored inconvenient facts which were discovered during oil field surveys. The ground is too soft to withstand an earthquake.”

Reassessments of submarine active faults were ordered by the Nuclear and Industrial Safety Agency for all Japanese nuclear power plants in June 2002. The reason given was that during the safety review for Hokkaido Electric’s planned Tomari-3 reactor a submarine fold was assessed to be a fault.

On 29 August 2002 it was announced that TEPCO had passed periodic inspections of its nuclear power plants by altering inspection data and concealing cracks. This was the first TEPCO scandal. After the scandal was revealed, TEPCO nuclear reactors shut down for periodic inspections could not be restarted and in the spring of 2003 operation of all 17 TEPCO reactors was suspended.

The reassessment of submarine active faults was being carried out in the middle of all this scandal.

As a result of the reassessments required by the government, active faults were reported on 25 May 2003 for Hokuriku Electric’s Shika nuclear power plant, on 16 June for TEPCO’s Kashiwazaki-Kariwa plant and in July for Chubu Electric’s Hamaoka plant. Active faults were also reported for Japan Atomic Power Company’s Tsuruga plant, Kansai Electric’s Mihama, Ohi and Takahama plants and for Chugoku Electric’s Shimane plant. In the case of Kashiwazaki-Kariwa, Shika, Tsuruga and Mihama, it was recognized that if these submarine active faults caused an earthquake, it could give rise to an earthquake ground motion exceeding the S1earthquake ground motion assumed when the licenses for these nuclear reactors were approved. However, this was concealed from the public on the grounds that the earthquake ground motion would not exceed the S2 earthquake ground motion.*1

The power companies and the government were afraid that a public announcement concerning these active faults would only increase public distrust towards them and it would become difficult to restart the nuclear power plants. Thus electric power supply was prioritized over safety. At the time, TEPCO was running a PR campaign claiming that it would enforce corporate ethics, put safety first and disclose information.

Likewise, TEPCO’s announcement on 5 December 2007 of submarine fault F-B was not spontaneous. Immediately after the Chuetsu-oki earthquake, a group of geologists had pointed out that the Chuetsu-oki earthquake*2 was caused by a submarine fault and questioned why this obvious submarine active fault had not been discovered. In the face of this professional challenge, TEPCO belatedly confessed that it was aware of the submarine active fault since 2003 and had reported it then to the government.

Footnotes

*1. For an explanation of S1 and S2 earthquakes, see the section, “Important safety equipment may have been seriously damaged”.

*2. See footnotes 4, 5 and 6 in the previous section “Earthquakes and Ground Condition – Just how Safe is the Kashiwazaki-Kariwa Nuclear Power Plant?”.

Materials get stronger when deformed by an earthquake!?

There is a line of thinking in TEPCO and NISA that equipment can still function OK after incurring plastic deformation (distortion), even though the design does not permit this. Hideo Kobayashi, a member of the working group assessing management and control and the integrity of equipment, made a very surprising statement at the working group’s first meeting (4 September 2007). He said, “The word ‘damage’ keeps coming up. The problem is that when [metal materials] incur very great plastic deformation, they actually become stronger, so in fact I think damage is not a worry.” The truth is that metal materials do not get stronger when they incur plastic deformation, they get harder. Hardening is a step along the path to brittleness.

No one says that blood vessels become stronger when hardening of the arteries occurs. It is totally unacceptable for equipment to be assessed to have maintained its integrity on the basis of the notion that metal materials get stronger when they incur plastic deformation and that damage is not a concern.

Hideo Kobayashi has made several peculiar remarks. For example, “I think questions of whether it’s OK or not OK by existing seismic standards and design standards are almost useless in this case. ‘Out’ is the only answer that you will get…” and “I would like the assessment to be carried out using actual values for strength and the latest scientific techniques, techniques not bound to existing regulations and standards.” NISA’s response to this was, “For equipment that shows no particular outward appearance of damage, where the seismic response exceeded the stress permitted under the seismic design in the approved construction plan, as you have pointed out, I believe it is necessary to carry out the assessment on the equipment’s actual strength.” It appears that the “actual strength value” is being used as the final escape route to allow the plant to operate, even if its distorted and damaged.

By a member of KK Scientists

Through the eyes of a power plant designer

What happened at the Kashiwazaki-Kariwa nuclear power plant?

It is reported that so far no serious damage to the equipment of the Kashiwazaki-Kariwa nuclear power plant has been found. How should we interpret this claim? When actually designing a plant, besides the seismic load, load arising from such things as pressure, temperature and weight are taken into consideration, so even if the seismic load is great, if its contribution to the total load is relatively small there might be no damage. Alternatively, there could be cases where some parts incur considerable damage, but this damage does not emerge on the surface and the total structure somehow manages not to collapse.

Besides damage to equipment, another important issue is whether the function of equipment related to the safety of the nuclear power plant is maintained after an earthquake. If an earthquake arises in the future while the plant is operating and, for example, control rods fail to insert due to the violent shaking, or pumps and valves in the emergency core cooling system*1 (ECCS) fail to function, this could lead to a runaway chain reaction*2 or a core melt down*3. The details are unclear, but a control rod could not be removed from the core of Kashiwazaki-Kariwa reactor 7 after the Chuetsu-oki earthquake. No matter what the circumstances, equipment that is so fundamental to the safety of the plant must not be allowed to fail. On those grounds alone, one would have to say that it would be a dangerous gamble to restart the plant.

Plant design must take into account the worst-case

The design must guarantee that the plant can withstand the worst-case situation. For example, in the case of an earthquake the shaking of the plant varies depending on the input spectrum*4 transmitted through the ground. If the period of the vibration does not match the natural period of the structures, equipment and pipes, they will not be severely shaken. However, if the periods match, they will resonate and the shaking will be amplified many times. In complex nuclear power plants it is possible that such large shaking could occur in many places and cause damage. The current case was the result of a strong force from earthquake ground motion accompanied by a particular spectrum. A different strong earthquake ground motion with a different spectrum would produce a different type of response in the plant. Also, different modes of operation (eg if the ECCS was in action) would produce different kinds of load besides the seismic load, so the damage is likely to be different.

When it was discovered that Japanese architects had faked the strength of buildings and that these buildings were not designed strong enough to withstand earthquakes, they had to be pulled down. In another case, people were killed by car wheel hubs, which flew off because they were not designed strong enough. In this case the manufacturer was held responsible in court for not recalling the cars. But here we have TEPCO carrying out analyses and assessments aimed at restarting the Kashiwazaki-Kariwa nuclear power plant. In situations where by rights the nominal value*5 for material strength should be applied, TEPCO is trying to apply the actual value*6. They chose a damping constant*7 which made the resonance response at the time of the earthquake appear small, even though the basis of this damping constant has not been confirmed.

It seems that TEPCO is attempting to respond by employing inadequately verified methods that designers know should never be used. These types of assessment methods are sometimes used for accident reviews and to assess, based on average values, situations which are most likely to arise, but they are precisely the wrong methods to use when discussing safety. One wonders whether the professors and officials on the working group assessing the integrity of the plant’s equipment understand the basics of plant design.

Start again from the design stage

We are talking about a nuclear power plant which, if an accident were to occur, would be expected to cause an irreversible disaster. With seven reactors, the Kashiwazaki-Kariwa Nuclear Power Plant is the biggest nuclear power plant in the world. It is our view that the earthquake ground motion should be redefined to take into account the “unforeseen” earthquake ground motion that occurred this time. We further believe that the resulting seismic load should be combined with the loads for all modes of operation and redefined and that the whole plant should be redesigned accordingly. Arbitrary values like the “actual strength value” should not be used for issues affecting safety. Instead, wherever in the light of standards used hitherto the strength is inadequate, the equipment should be rebuilt. Unless that is done, it is unthinkable that the plant could be restarted.

Footnotes

*1. Safety system to inject water into the reactor core in an emergency to prevent overheating.

*2. Failure to control nuclear fission leads to an explosive chain reaction. This is the worst type of nuclear accident. The Chernobyl accident was of this type.

*3. Overheating of the reactor core due to lack of coolant leads to melt down of the nuclear fuel and core internals. If this situation continues a 3-Mile Island type accident occurs. This situation can also arise from a runaway chain reaction.

*4. Earthquake ground motion spectrograph: a graph showing the strength of the shaking from the earthquake for each period.

*5. Value for the lower limit of strength determined for a particular material.

*6. Not the nominal value, but the assumed strength of a material being used.

*7. Vibration damps away with time. The damping constant is a coefficient appearing in the equation of vibration; the higher the value of this coefficient, the faster the rate at which the vibration dies out. For example, a value of 2% is used in an analysis of the present assessment instead of 0.5% employed in the design.