Current State of Post-Accident Operations at Fukushima Daiichi Nuclear Power Station (May to end October 2014) Nuke Info Tokyo No. 163

State of the Plant

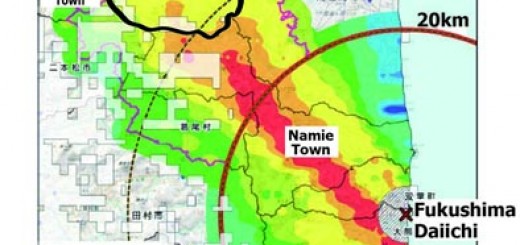

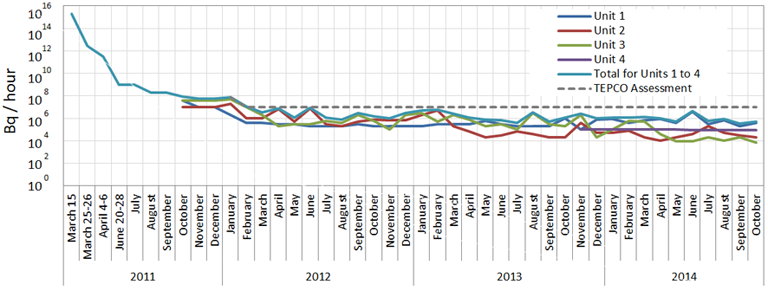

Many of the measuring instruments installed in the Fukushima Daiichi Nuclear Power Station (FDNPS) measuring system continue to malfunction as a result of the accident. Although there is no guarantee of the accuracy of values being measured, if these values are taken as the premise, from the water temperature in the containment vessels and the spent fuel pools, and from the releases of Xenon-135, it can be estimated that the state of the reactors is stable. Up to now, Tokyo Electric Power Company (TEPCO) has assessed releases of radioactive substances into the atmosphere at 10 million Bq/h However, from the fact that the state of the reactors is stable and that releases continue to be at a low level, from May TEPCO has used the expression “less than” 10 million Bq/h. (See Figure 1)

|

| Figure 1. Releases of radioactivity from Units 1 to 4 of Fukushima Daiichi Nuclear Power Station From materials prepared and submitted by the secretariat to the Government and TEPCO’s Mid-to-Long Term Countermeasure Meeting and Secretariat of the Council for the Decommissioning of TEPCO’s Fukushima Daiichi Nuclear Power Station. (However, this was for assessing leakage from exhaust outlets and gaps in building covers and does not include leakage to groundwater, etc.) |

Current State of Post-Accident Operations

1. State of Operations concerning Molten Fuel

The current state is that for each of the reactors, surveys of the plant situation as preparation for decontamination of the buildings, surveys to reveal the locations of leaks in the containment vessels, as well as R&D work on various kinds of devices, are being implemented in parallel.

2. State of Operations concerning Spent Fuel Pools

The removal of fuel assemblies from Unit 4 began in November 2013, and of the 1,535 assemblies that were being stored in the Unit 4 spent fuel pool at the time of the accident, 1,331 spent fuel assemblies have been transferred to the common pool (announcement of November 5, 2014). The transfer of all spent fuel from Unit 4, including the three damaged assemblies that had been stored in the spent fuel pool since before the accident, is due to be completed by the end of November. Due to lack of capacity in the common pool, fresh fuel in the Unit 4 spent fuel pool will be transferred to the Unit 6 spent fuel pool (scheduled for completion in December).

Removal of large debris from the operating floor of Unit 3 is now complete. At present, measures are being taken to reduce the radiation dose level, but the level is still far above the target of 1 mSv/h and additional measures are now being considered. The construction work to put in place the cover for removal of the fuel is scheduled to begin in the near future. Moreover, on August 29, an accident occurred in which the operating console of the spent fuel pool fuel handling machine and other large debris fell into the pool.

The dismantling of the cover now in place around the reactor building of Unit 1 was due to begin in July 2014 in order to carry out the work of removal of debris from the operating floor, but this task has been delayed due to the inadequacy of measures to suppress the dispersal of radioactive substances. (Application of an anti-dispersal agent is now being implemented and it is planned to start debris removal in March 2015.) The schedule for removing spent fuel has been delayed from 2017 to 2019, and removal of molten fuel from 2020 to 2025.

While there is no great damage to the Unit 2 reactor building, high dose rates have made it impossible to confirm details of the state of the interior of the building. The construction method for the cover for removal of the nuclear fuel was to be determined during the first half of 2014, but this decision has now been delayed until mid-2016.

Additionally, the fuel assemblies removed from the spent fuel pools in each of the reactor buildings are to be stored in the common pool, but since there are concerns over storage of damaged fuel a special storage rack for damaged fuel has been installed.

3. The Problem of Contaminated Water

According to an estimate by TEPCO, roughly 800 m3 of underground water are flowing into the reactors of Units 1 to 4 per day, 400 m3 of which is flowing into the reactor buildings and the remaining 400 m3 being released into the ocean.

The following measures are being planned to suppress the inflow of groundwater:

1) A groundwater bypass to reduce the inflow of groundwater by pumping the water up using pumping wells installed on the land side of the site and releasing the water into the ocean. The pumping of underground water began in April 2014, and the water pumped up is being released into the ocean after confirmation that the radioactivity in the water is below the standard. According to the plan, the amount of groundwater prevented from flowing into the buildings is 50 m3/day. TEPCO says that in combination with the water prevention measures in the high-temperature incinerator building, a reduction of 90 m3/day was seen as of October 14.

2) Pumping up groundwater from the subdrains in the vicinity of the buildings and releasing the water into the ocean. In addition to the existing 27 subdrains, 15 new subdrains have been constructed, and experimental operations with these began from September 2014. TEPCO says that it is releasing this pumped up groundwater into the ocean after purification, but as the pumped groundwater is clearly contaminated, opposition from nearby fishery cooperatives has been steadfast, and implementation has not yet begun as of end October.

3) Construction of an inland water barrier. A frozen earth barrier is to be created by burying 749 refrigeration pipes and 151 temperature measuring tubes at set intervals around Units 1 to 4. Installation work began in June and the barrier is scheduled to begin operation in the first half of FY2015.

4) Construction of an ocean side water barrier. This was scheduled to begin operation around September 2014, but has not yet been implemented since it is conditional upon the release of groundwater from the subdrains.

5) Prevention of water leakage from the Unit 1 to 4 reactor buildings through holes, etc. in the outer walls of the buildings. (Scheduled to be completed in FY2017.)

6) Operation of the Advanced Liquid Processing System (ALPS). The existing three ALPS plants were scheduled to be fully operational in mid-2013, but are experiencing frequent problems. Hot experiments with the added ALPS3 plant and the high-performance ALPS1 plant, built with a government subsidy, began in September and October.

7) An increase in the number of waste water tanks. Tanks to store contaminated water and purified water that still contains Tritium were to be increased to a total of around 800,000 m3 by the end of FY2014, but a further 100,000 m3 was added to this in July, when it was announced that storage for a total of 930,000 m3 of water would be installed.

8) Removal of contaminated water from trenches. Removal of contaminated water from branch trenches was completed in September 2013. Preparatory work to remove contaminated water from the main trenches began with an attempt to prevent water leakage by freezing the water in the junctions between the buildings and the trenches, but as it proved impossible to freeze the water, the insertion of packing material began on October 16.

In addition, in order to prevent direct flow into the ocean when contaminated water leaks from the storage tanks, of the drainage canals onsite, the C drainage canal, which is directly connected to the ocean, was altered in July to flow into the harbor.

(Hajime Matsukubo, CNIC)