Current State of Post-Accident Operations at Fukushima Daiichi Nuclear Power Station February to June 2015

State of the Plant

Many of the measuring instruments installed in the Fukushima Daiichi Nuclear Power Station (FDNPS) measuring system continue to malfunction as a result of the accident. Although there is no guarantee of the accuracy of values being measured, if the values from the measuring instruments are taken as the premise, from the water temperature in the containment vessels and the spent fuel pools, and from the releases of Xenon-135, for example, it can be estimated that the state of the reactors is stable.

Current State of Post-Accident Operations

1. State of Operations concerning Spent Fuel Pools

Removal of all of the fuel assemblies stored in the Unit 4 spent fuel pool (SFP) was completed on Dec. 22, 2014.

Measures are being implemented at Unit 3 to reduce the radiation dose level in preparation for the work of removing the fuel. Furthermore, preparatory work for removal of large pieces of debris is currently being carried out in the Unit 3 SFP. The debris fell into the pool in an accident that occurred in August 2014.

The work to dismantle the cover in place around the Unit 1 reactor building began on May 15. As preparatory work for dismantling the cover, application of an anti-dispersal agent was implemented to prevent dispersal of radioactive substances remaining in the building. On May 21, it was discovered that the balloon installed in June 2014 to block the equipment hatch opening was out of position. As a result, the work to dismantle the cover roof panels from the Unit 1 building that had been scheduled for late May had to be postponed.

There has been no great progress in Unit 2.

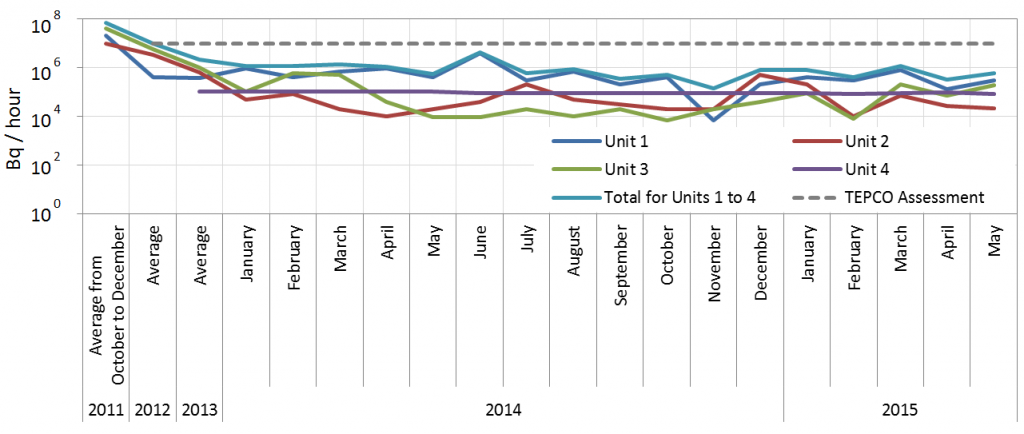

Figure 1. Releases of radioactivity from Units 1 to 4 of Fukushima Daiichi Nuclear Power Station (Bq/h)

* An assessment by TEPCO shows 10 million Bq/h up to May 2014, and less than 10 million Bq/h after May 2014

2. The Problem of Contaminated Water

According to an estimate by Tokyo Electric Power Company (TEPCO), roughly 800-1,000 m3 of groundwater is flowing into FDNPS Unit 1 to 4 per day, about 300 m3 of which is flowing into the reactor buildings.

Measures taken to suppress the flow of groundwater are as follows:

- Groundwater pumping wells have been installed on the mountain side of the site as a “groundwater bypass,” to reduce the inflow of groundwater by pumping it up and releasing it into the ocean after measuring its contamination level. (This operation began in April 2014, with a total of 112,748 m3 water having been released in 71 releases, up to June 30, 2015. Combined with the water suppression measures taken at the high-temperature incinerator building, this operation reduced the groundwater inflow by 80 m3 per day.)

- It is planned to pump up groundwater from the sub-drains in the vicinity of the reactor buildings and from the groundwater drains near the embankment (roughly 50-100 m3 of water from the groundwater drains and roughly 500-700 m3 from the sub-drains per day. This is expected to reduce groundwater inflow into the buildings by 150 m3 per day.) TEPCO plans to release the pumped-up water into the ocean after purification.

- Construction of an inland water barrier (creation of a frozen earth barrier by burying 1,551 refrigeration pipes and 336 temperature measuring tubes at set intervals around Unit 1 to 4. Freezing of the water barrier started on a trial basis on April 30 at 18 locations using 58 freezing tubes.)

- Removal of highly contaminated water flowing from the buildings into trenches on the sea side. (After having failed to stop the water by freezing it at the junctions between the trenches and the buildings, the insertion into the Units 2, 3 and 4 trenches of packing materials consisting of a mixture of concrete and other materials was begun on October 16, 2014. Preventing leaks and removing contaminated water from Unit 4 was completed on April 28, though part of this project was suspended. Removing contaminated water from Unit 2 and 3 was scheduled to be carried out before the end of June.

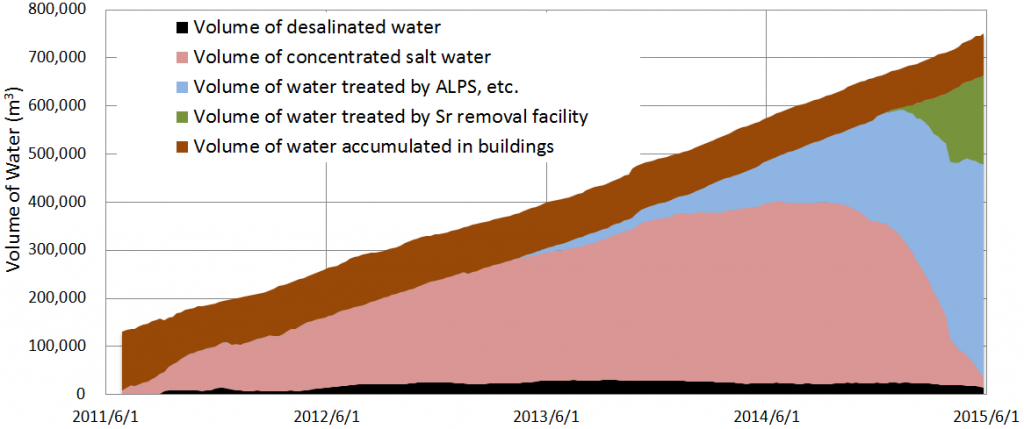

- Operation of the Advanced Liquid Processing System (ALPS – Three existing systems, three additional ALPS systems, and a high performance ALPS system). These are used to separate contaminants, including nuclides, from contaminated water, although tritium still remains in the treated water, and to reduce the strontium content of concentrated salt water. (Reduction of strontium in concentrated salt water was completed on May 27. See Figure 2 for total volume of contaminated and treated water accumulated in buildings and tanks).

Figure 2. Total Volume of Contaminated and Treated Water Accumulated in Buildings and Tanks (as of May 28, 2015)

Desalinated water is circulated to cool the reactors after cesium salt removal.

3. Others

The number of workers at FDNPS is expected to increase from around 2,950 daily as of March 2013, to 6,800 in July 2015. May 31, 2015 saw the opening of a large rest house built on the plant’s premises for the purpose of improving the working environment.

On February 24, 2015, TEPCO announced that the highly radioactive water that had accumulated on the roof of the large equipment service entrance of the Unit 2 reactor building had been flowing into the open ocean through a drainage channel. Although the utility became aware of this fact sometime before April 2014, it did not disclose the leakage to the public. Local fishermen reacted strongly against the company’s announcement, and as a result, their negotiations with TEPCO on the release of the contaminated sub-drain water will have to start all over again from scratch.

On April 2, 2015, a pool of water was discovered at the periphery of the lid of a high integrity container (HIC), a polyethylene container for storing slurry created in the preprocessing systems of ALPS and other systems, slurry from the the adsorption tower, and also for storing spent adsorbent. This prompted TEPCO to conduct an investigation of the HICs. The result was that similar pools of water were found on 30 of the 684 HICs inspected up to June 15. After confirming slurry precipitation, TEPCO removed water from 32 of the HIC containers.

On May 27, the work to dismantle the flange-type tanks (374 in total) began, and 40 of them are slated to be dismantled by the end of January 2016. Leakage of contaminated water from this type of tank has occurred frequently, but it has yet to be decided if all of the flange-type tanks should be dismantled.

On April 30, 2015, the Nuclear Damage Compensation and Decommissioning Facilitation Corporation released its “Technical Strategic Plan 2015 for Decommissioning of TEPCO’s Fukushima Daiichi Nuclear Power Station.” Based on this plan, the mid-term and long-term roadmaps for the plant’s decommissioning were revised, and TEPCO finalized this revision on June 12. The utility has regretted that its traditional stick-to-schedule work policy put excessive pressure on workers, causing a number of problems at the plant. The company therefore changed its policy and gave priority to the reduction of risks. Although the scheduled time for completing the decommissioning work remains the same, the period given for removing spent nuclear fuel was extended for up to three years. The stick-to-schedule policy was a target of popular criticism from the very beginning, and TEPCO seems to have eventually succumbed to the pressure after myriad troubles occurred at the nuclear accident site.

(Hajime Matsukubo, CNIC)