Fukushima Now (27) Part 2, Current State of Post-Accident Operations at Fukushima Daiichi Nuclear Power Station (February to July 2024)

By Matsukubo Hajime

State of the Plant

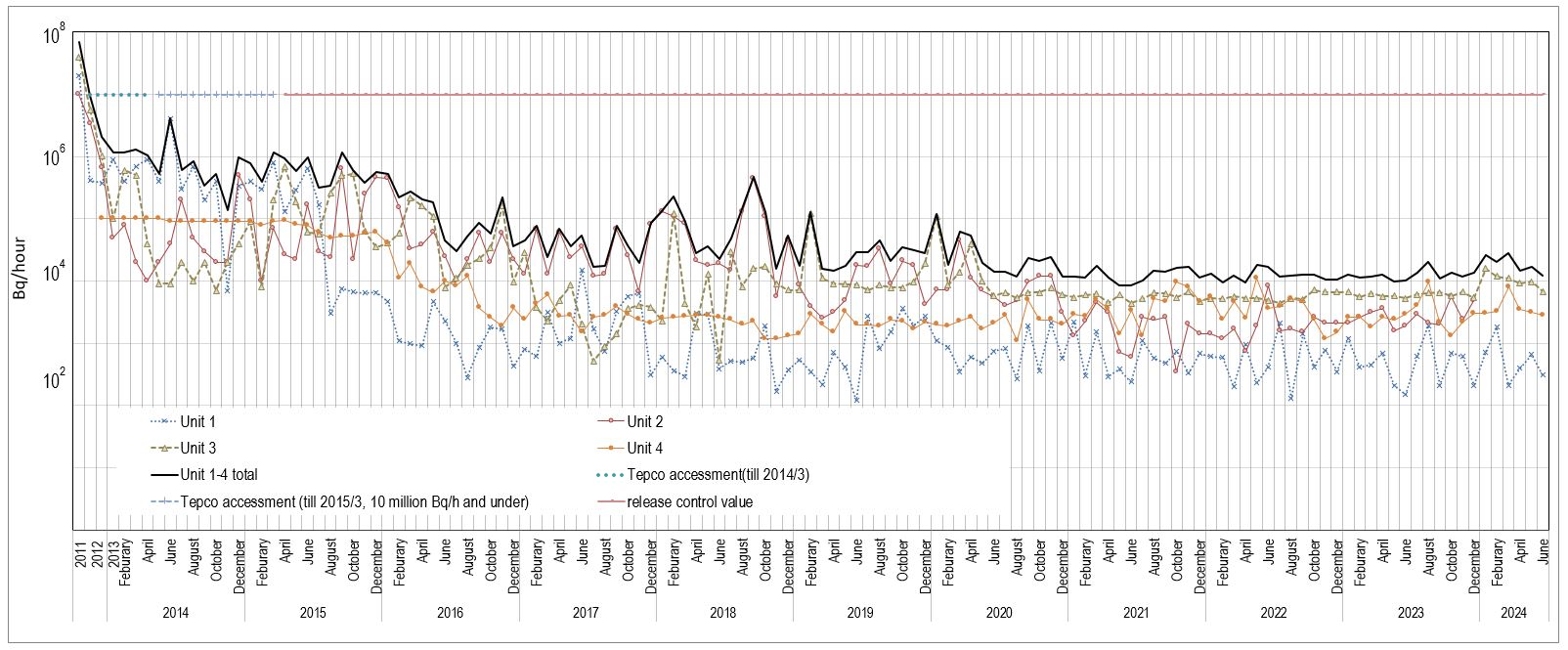

The water temperature in the containment vessels and the spent fuel pools (SFPs) shows no great variation despite seasonal temperature changes. The state of releases of Xenon-135 (half-life roughly nine hours), released when uranium fuel undergoes fission, is also unchanged and it can therefore be estimated that the state of the reactors is stable. Further, around 12,000 becquerels per hour (Bq/h) of radioactive materials were being released to the atmosphere from the buildings (TEPCO assessment in June 2024, Fig.1).

Fig.1. Radioactivity from Units 1 to 4 of Fukushima Daiichi Nuclear Power Station (Bq/h) released to the air

At the same time, decay heat has fallen greatly with the passage of time, and thus the volume of cooling water injected into the reactors has been reduced (falling from 7-10m3 per hour in May 2011 to 1.6-3.8m3 per hour as of December 2023). In particular, the water level in the doughnut-shaped suppression chamber (S/C) under the pressure containment vessel in Unit 1 is high. As there is a concern about damage from earthquake tremors, the amount of water injected into the S/C has been reduced in stages since March (3.7m3/h in February to 2.5 m3/h in July). The water level before the reduction in injected water was around 8.5m from the bottom of the S/C, and this has now gone down to about 7.1m. As the bottom of the drywell (D/W), a flask-shaped object in the upper part of the pressure containment vessel, has around 1m of deposited material (debris, etc.) from pre-accident times and it is estimated that the upper part of the deposited material is about 7.5m above the bottom of the S/C, it is thought that the deposited material is exposed above the surface of the water.

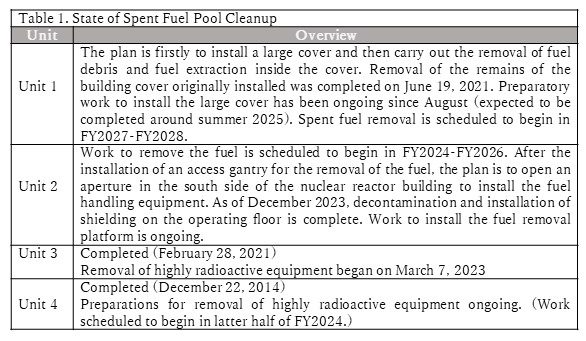

The state of removal of spent nuclear fuel from the SFPs is summarized in Table 1. Spent nuclear fuel removal from Units 3 and 4 has been completed. Preparations are now being made to remove the spent nuclear fuel from Units 1 and 2.

Spent nuclear fuel removal from Units 3 and 4 has been completed. Preparations are now being made to remove the spent nuclear fuel from Units 1 and 2.

The removal of fuel debris has been delayed. Experimental removal using a removal device (a folding robot arm of 22m in length) originally scheduled in the Mid-term Roadmap to take place in Unit 2 in FY2021 has been delayed (for the third time) until October 2024. Having been delayed due to the COVID-19 infection and then malfunctioning of the removal device, trouble has also been experienced opening the reactor vessel penetration hatch (X-6 penetration) to be used to insert the device. The hatch having been opened, it was found that cables, etc. inside the penetration, which melted during the accident, have fused and are lying in a heap. TEPCO built a device to push away the accumulated material, and this was completed on May 13 (originally scheduled to be completed at the end of FY2023). The policy now is to use an experimental telescopic-type removal device, differing from the robot arm removal device, that can be inserted into the hatch without removing remaining accumulated material. This device will be used to extract debris on an experimental basis from August to October, and then from the end of FY2024 through to FY2025 the robot arm removal device will also be used to extract debris. In addition, investigations are ongoing due to water level reductions occurring in the Unit 1 pressure containment vessel (PCV) and Unit 3 PCV and suppression chamber.

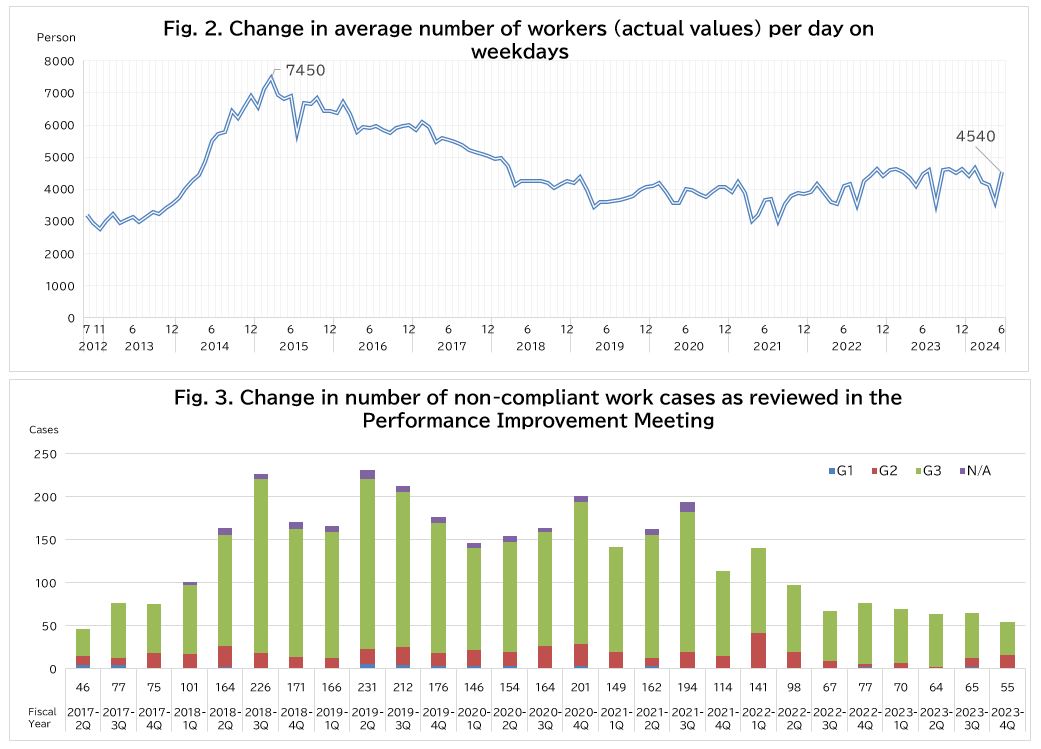

Changes in the average number of workers onsite per day is shown in Fig.2.  As of June 2024, the number of workers was 4,540. The number of reports of non-compliant work cases is trending downwards, but serious events have occurred in rapid succession.

As of June 2024, the number of workers was 4,540. The number of reports of non-compliant work cases is trending downwards, but serious events have occurred in rapid succession.

State of Contaminated Water

Contaminated water countermeasures at Fukushima Daiichi Nuclear Power Station (FDNPS) can be broadly divided into three areas: 1) Reduction of groundwater flowing into buildings, 2) Reduction of contaminated water flowing into the sea, and 3) Reduction of the toxicity of contaminated water. The main countermeasures to reduce water inflow into the buildings are, from higher elevations downward, (A) Pumping up groundwater at the groundwater bypass and releasing it into the sea (917,626m3 up to August 16, 2024), B) Installation of a frozen earth barrier (on-land water barrier, total length roughly 1,500m) surrounding FDNPS Units 1-4. C) Pumping up water at the subdrains and releasing it into the sea (1,723,123m3 up to August 15), and D) Paving of the site with asphalt to suppress permeation of rainwater into the soil. Measures to prevent the discharge of contaminated water into the ocean include A) Groundwater leakage prevention by a steel water barrier on the sea-side, B) Pumping up of groundwater dammed up behind the sea-side water barrier from the well points and groundwater drains. Due to these measures, the volume of contaminated water discharged, 540m3/day in May 2014, fell to 80m3/day in FY2022, partly due to the fact that there were no intensive rainstorms during that year.

In the reduction of the toxicity of contaminated water, cesium, and strontium are removed, and after the removal of impurities using a reverse osmosis (RO) membrane, the multi-radionuclide removal equipment (ALPS – Advanced Liquid Processing System) is then said to remove 62 radionuclides. The water is then stored in tanks (containing 1,312,262m3 as of August 1, 2024. However, due to past equipment malfunctions and operational policies, around 64% of the stored water exceeds the notification concentration). Oceanic release of the ALPS-treated contaminated water began on August 24, 2023, a total of 23,589m3 being released in six batches by July 2024. Further, roughly 14,390m3 of water remain in buildings, as well as 10,461m3 strontium-treated water, etc., 6,346m3 water treated by RO, and 9,415m3 concentrated wastewater, etc. also exist onsite.

While no new accident information was registered on NUCIA last time, information concerning eight accidents, from October 25, 2023 to June 18, 2024, were registered on August 5. Many of the incidents registered are industrial accidents, work mistakes, or both. This makes it possible to catch a glimpse of how much pressure is involved in the work at the site

|

List of Accidents at Fukushima Daiichi Nuclear Power Station (September 2023 to July 2024) (Excerpted from the Nuclear Facilities Information Archive (NUCIA)) |

|||

|

Date |

Location |

Summary of Accident |

NR* |

|

Oct. 25, 2023 |

Expanded ALPS

|

During cleaning work in the outlet piping (system B) of the crossflow filter of the expanded ALPS, stopped for inspection, a temporary hose became detached from the receiving tank to which waste cleaning liquid was being transferred. Two workers of a subcontractor company who were carrying out the work in the vicinity were sprayed with the waste cleaning liquid. As a result of contamination measurement of the five workers who were involved out the same work in the vicinity, body contamination was confirmed in the two persons who were sprayed with the waste cleaning liquid and two persons who were engaged in cleaning up the spilt water. The decontamination of the two persons who carried out the cleaning up of the spilt water was completed, but the two persons who were sprayed with the waste cleaning liquid were taken to the hospital, as it was difficult to decontaminate them to a value below the exit standard (4Bq/cm2). |

|

|

Feb. 7, 2024 |

High-temperature incinerator building

|

Subcontractor company workers confirmed that water was leaking from piping on the east wall of the high-temperature and high-pressure incinerator. The area of the leakage was about 4 m×4 m×1 mm in depth on iron plates below the leakage point. There was a possibility that the leaked water had seeped into the soil through gaps between the iron plates. The result of a smear measurement showed 72,000cpm (background: 300cpm). |

〇 |

|

Feb. 22 |

Expanded miscellaneous solid waste incineration facility

|

The fire alarm of the waste storage pit on the fifth floor of the expanded miscellaneous solid waste incineration building sounded. It was confirmed that there was no source of fire at the site, but it was later reported to the fire department as it was impossible to check the site due to steam. Continuous efforts were made to flush the steam, but as it was not possible to ventilate remaining steam, water was injected into the pit. (The total volume of injected water was around 1,200m3.) |

|

|

Mar. 19 |

Outside Unit 1 reactor building

|

A subcontracting company worker was injured when his right ring finger was caught in a tool while tightening a bolt outside the Unit 1 reactor building on the premises of the power station. The injury was diagnosed as an open fracture of the tip of the right ring finger. |

|

|

Apr. 22 |

Unit 2 fuel extraction gantry

|

A subcontracting company worker was injured when his finger was caught in the steel frame during installation of the walkway steel frame on the fuel extraction access gantry in Unit 2. He was diagnosed with an open fracture of the tip of the right middle finger. |

|

|

Apr. 24 |

West side of the large equipment inspection building

|

Around 10:43AM on April 24, the onsite power supply system A failed, and the ALPS treated water dilution and discharge facility, discharging at the time, stopped automatically. (Operation resumed at 5:16PM). At the same time as when the onsite power supply system A failed, it was confirmed that a subcontracting company worker who was engaged in excavation work to scrape off the surface layer of the concrete paving on the west side of the large equipment inspection building on the site was injured. The onsite power supply system A failed due to a cable being damaged by the excavation work. The injured person was diagnosed with “second-degree burns to the right cheek and right forearm.” |

|

|

May 23 |

Solid waste storage shed |

A subcontractor company worker who was supplying ready-mixed concrete near the solid waste storage building No. 10 slipped off a ledge (about 1m in height) and fell to the ground. He was diagnosed with a left ilioacetabular fracture. |

|

|

Jun. 18 |

Unit 6 |

The power supply of Unit 6 M/C (high-voltage power supply panel) 6C failed, causing the diesel generator 6A to start automatically. At the same time, the pump (B) of the spent fuel pool cooling and purification system of Unit 6 tripped. Burning was confirmed in the undivided bus near the ceiling of the first basement of the Unit 6 turbine building. |

|

* NR: Notification required by law.