First MOX Powder Produced at Rokkasho Nuke Info Tokyo No. 115

As reported in previous issues of NIT, active tests at the Rokkasho reprocessing plant began on 31 March 2006. The plan is to reprocess 430 tons of spent fuel over 17 months in 5 steps of gradually increasing quantities: 30 tons, 60 tons, 70 tons, 110 tons and 160 tons respectively.

The first step, the main aim of which was to shear and dissolve 30 tons of spent fuel, was completed on June 26th. However, commencement of the second step was delayed so that measures could be taken to prevent a repetition of the worker exposure incidents that occurred in the latter half of the first step. Two cases of worker exposure occurred in the analysis laboratory due to problems such as insufficient understanding regarding handling of equipment and the failure of workers to wear masks (NIT 113).

The commencement of the active tests marked the beginning of the release of krypton-85 into the environment. During shearing of spent fuel, the concentration of beta radionuclides downwind of the plant reached 2 kilo-becquerels per cm3 for the first time ever and the concentration of krypton in the atmosphere also increased accordingly. Official data on liquid emissions has not yet been released.

Delay during step 2

Shearing of spent fuel for step 2 commenced on August 18th, but the following day problems arose with the shearing machine and shearing was suspended for the next month. According to a problem report released by Japan Nuclear Fuel Ltd. (JNFL) at the end of September, something had lodged in the shearing machine. Whatever it was could not be removed by the usual method, so a new method had to be used. JNFL recommenced shearing on October 2nd without providing any detailed account of the problem which had caused the suspension.

As a result of the problems with the shearing machine, by the end of September only 6 PWR fuel assemblies (about 3 tons) had been sheared during step 2. This delay could potentially cause the schedule for commencement of “commercial” operations to be set back. To avoid this, JNFL proceeded at a rapid pace after it recommenced shearing, at times reaching the maximum pace envisaged under full-scale operating conditions of 4.8 tons a day. Clearly JNFL is trying to make up for lost time. However, if there have been delays during the active tests, naturally these delays should be reflected in the schedule for commencement of “commercial” operations. JNFL should take the utmost care during these tests. By prioritizing schedules, JNFL is putting extra pressure on workers. This will cause them to become stressed and exhausted. We fear this will only cause more problems and accidents.

First MOX powder produced

All 50 tons of PWR spent fuel scheduled to be sheared and dissolved during step 2 were completed late October and shearing and dissolving of BWR spent fuel commenced mid-November. Testing of the processes of blending uranium and plutonium solutions and denitration of uranium and mixed plutonium-uranium solutions began for the first time at the beginning of November, and on November 16th JNFL announced that Rokkasho’s first MOX powder (the finished product) had been produced.

|

|

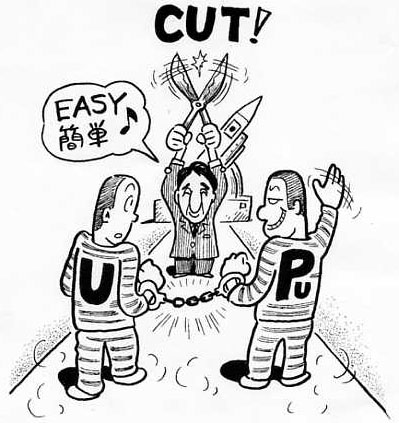

Cartoon by Shoji Takagi

|

The mixed oxide denitration process is a major difference between the Rokkasho reprocessing plant and the reprocessing plants in France and the UK. This process was a requirement of a 1977 Japan-US joint decision regarding reprocessing at the Tokai reprocessing facility. Uranium nitrate and plutonium nitrate solutions are mixed in a 1:1 ratio. The nitrate component is then removed from this mixture to create a mixed oxide (MOX) powder. The Carter administration firmly demanded this process as a non-proliferation measure and the original design of the Tokai facility was altered to accommodate the US position. The process employed at Rokkasho is essentially the same as that used at Tokai.

A portion of the MOX powder produced at Rokkasho will be shipped to Tokai Village to be used at the mock-up JMOX test facility that has been set up there. JMOX is the name of the MOX fuel fabrication plant that will be built next to the Rokkasho reprocessing plant. It is not scheduled to commence operations until 2012. In the meantime a test facility has been set up in Japan Atomic Energy Agency’s Plutonium Fuel Production Facility at Tokai.

One man’s fuel is another man’s bomb material

It is a great irony that production of plutonium-uranium mixed oxide powder began at Japan’s first industrial-scale reprocessing plant a month after North Korea conducted a nuclear weapons test. It is believed that the weapon tested by North Korea was a plutonium bomb. While North Korea might have extracted enough plutonium for a few nuclear weapons, when fully operational Rokkasho will produce enough plutonium each year to produced 1,000 such weapons.

The Japanese government and nuclear industry persist with their claim that the mixed oxide denitration process described above is proliferation-resistant. The International Atomic Energy Agency takes a different view. The IAEA’s Safeguards Glossary lists MOX as follows: “MOX is considered a special fissionable material…and a direct use material”. “Direct use material” is further defined as “nuclear material that can be used for the manufacture of nuclear explosive devices without transmutation or further enrichment.” Japanese officials and industry representatives may be able to repeat the old fiction without blinking, but other than the Japanese public no one is deceived. While we do not believe that Japan has a nuclear weapons program or that the government intends to produce nuclear weapons in the foreseeable future, Japan’s plutonium program is an obstacle to non-proliferation and disarmament. The best service Japan could do for these causes would be to close down the Rokkasho reprocessing plant and abandon the illusion of plutonium as an inexhaustible fuel source (see also page 7).

Masako Sawai and Philip White (CNIC)