Nuclear Power Station decommissioning Schedule-first policy placing excessive burdens on workers TEPCO has responsibility to protect workers’ health and jobs. Nuke Info Tokyo No. 163

Three years and eight months have passed since the outbreak of the nuclear crisis in Fukushima, yet the situation at the crippled Fukushima Daiichi nuclear power station (NPS) is nowhere near completion of the clean-up operations after the 2011 nuclear accident. The number of operations dealing with leaking radioactive water is increasing sharply at the plant. Such operations include the construction of additional tanks for storing contaminated water, reinforcement of the advanced (multi-nuclide) liquid processing system (ALPS), and the work to freeze the junction between the underground trench on the seaside and the nuclear reactor building. In addition, some large-scale projects are underway, for example, the construction of a new office building, a facility for managing workers’ entry and departure, and a facility for incinerating protective suits and other contaminated articles.

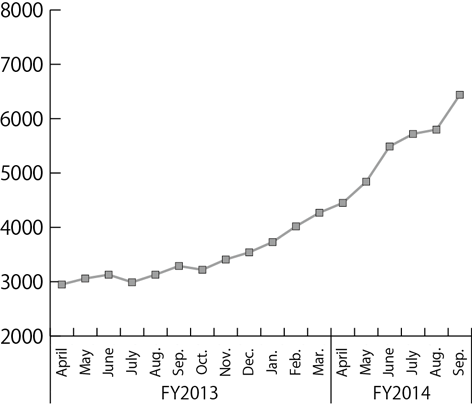

Until 2013, the number of workers engaged in the plant’s accident clean-up operations allegedly averaged 3,000 per day, but the number began rising steeply this year. The Tokyo Electric Power Company (TEPCO) announced at its regular press conference on October 30 that a total of 6,000 – 6,400 workers have been working at the site daily since mid-October (Figure 1).

|

| Figure 1. Changes in the daily mean number of workers after FY2013 (results) |

Accidents and worker injuries increasing sharply at work sites

Amid this situation, the number of accidents and worker injuries are surging rapidly. On November 7, a heavy piece of construction material weighing 390 kg fell on top of three workers engaged in work to build tanks for storing processed radioactive cooling water. They sustained serious and light injuries. One worker suffered damage to his spinal cord and fell into a coma. He was taken to Fukushima Medical University by helicopter, accompanied by a medical doctor, and recovered consciousness there, but he still remains in a critical condition. One of the other two workers sustained a bone fracture on his ankle, and the third worker, bruises on both legs. These two workers were taken to Iwaki Kyouritsu Hospital by the prefecture’s emergency helicopter. The three workers are employees of a subcontractor of Tokyo Power Technology Ltd. which is a TEPCO subsidiary.

The accident occurred in an area known as “J2.” When workers from IHI Plant Construction Co. and others were trying to adjust the position of a steel section on top of the 2,400-ton welded-type tank to which a ladder was to be attached, the 25m-long semicircular steel section dropped from a height of 13 meters above the ground. The steel section fell onto the ground, rebounded upwards and hit the three workers, who were engaged in the work of building a barrier against possible water leaks around an adjacent tank.

Earlier, a similar accident occurred in the same area where work to construct additional tanks was underway. On September 20, an iron pipe was dropped, injuring a worker.

TEPCO to review roadmap for the decommissioning of Fukushima NPS Unit 1

The work to remove the spent nuclear fuel from the Unit 4 pool was completed on November 5. At the time when the 2011 nuclear accident occurred, the total of 1,535 nuclear fuel assemblies in the Unit 4 pool included 1,331 spent fuel assemblies and 204 fresh fuel assemblies. When the cooling-water circulation stopped, the nuclear fuel posed a grave threat. The remaining 180 fuel assemblies in the pool were unused ones that have a relatively low level of radioactivity. The utility plans to remove these assemblies as well, before the end of this fiscal year. If this work is completed, the risk from Unit 4 will be reduced to almost zero. However the nuclear fuel assemblies in Units 1, 2, and 3 remain in their spent fuel pools.

On October 30, TEPCO announced that it would review its plan to begin removing spent nuclear fuel from the Unit 1 pool in the first half of fiscal 2017 at the earliest. The utility said it will postpone this work for two years, to sometime in FY2019. The utility also announced that it would reschedule its plan to begin removing the molten nuclear fuel in the reactor from the first half of FY2020 to FY2025.

Previously, TEPCO has moved schedules forward, but this is the first time that the utility has delayed plans. By admitting that there will be delays in its work to remove the nuclear fuel, TEPCO is revising its plans for decommissioning of Fukushima Daiichi NPS.

One of the reasons for the rescheduling is that the work to remove part of the canopy above the Unit 1 building has been delayed for more than six months. Another reason is that TEPCO has changed its original plan to make alterations to the canopy and use it for the work to remove the spent nuclear fuel. Instead, it plans to remove the canopy and construct a new framework specially designed for the fuel removal operation on top of the reactor building. As for the work to remove the molten nuclear fuel, the utility is set to dismantle the existing framework, and install a different one designed exclusively for the removal operation.

To date, the workers engaged in the cleanup operations have been forced to work illegally long hours as they are ordered to hurry to get the work completed according to the schedule. It is reasonable for TEPCO to review the work schedule by attaching greater importance to reality, and pay less heed to its groundless slogan of “achieving decommissioning in 30-40 years.”

In fact, a concrete path to decommissioning of the nuclear reactors has yet to come in sight. It still remains unknown exactly how the reactors are damaged or what the condition of the molten nuclear fuel is.

When removing the molten nuclear fuel, the containment vessel is to be flooded with water to provide shielding from strong radiation during the removal procedures. However, cooling water that is being poured into the vessels continues to leak. In preparation for the repair of the containment vessel, an investigation is being conducted by using a robot. Nevertheless, the points from which the cooling water is seeping have not been determined, and the technical method for taking out the molten nuclear fuel has not yet been decided.

The work schedule published by the government and TEPCO gives the impression that the work would progress in due course of time, but most of the proposed schedules are not based on reliable grounds and most are still under consideration.

Despite this situation, workers are ordered to give top priority to doing their jobs on schedule. “We are strongly pressured to do our jobs on schedule and even a one-day delay is not tolerated,” said a worker. He went on to say, “In the Fukushima Daiichi NPS, many workers are assigned to new tasks for which they have no previous experience. Sometimes the work is delayed by bad weather. The more strongly they order us to stick to schedule, the more difficulties we will face.”

While the workers are struggling with this situation, the review of the work schedule was carried out to reflect such realities in the schedule. Yet, at a joint meeting to discuss the work schedule, the government urged the utility to accelerate the timetable.

Growing numbers of workers engaged in water-shutoff operations above contaminated water are registering limit-over cumulative radiation exposure

In the work to freeze the junction between the seaside underground trench and the reactor building, workers are being forced to expose themselves to high-level radiation at 0.4 mSv for six hours per day. As it is not possible to freeze the water by inserting the cooling pipes alone, workers have been working round the clock inserting massive amounts of ice and dry ice into the water manually. These efforts, however, did not produce good results and the water did not freeze. Now they are pouring cement into the gaps between the cooling pipes and the reactor building to block the water flow. (See NIT162, Contaminated Water Woes at Fukushima Daiichi: Is Seepage Control Possible Using a “Frozen Earth Barrier”?)

At a meeting of the Nuclear Regulatory Commission (NRC), a TEPCO official in charge of the frozen earth barrier operation stressed that the utility is striving to reduce worker exposure by, for example, providing them with radiation-proof tungsten vests, and transferring heavily-exposed workers to work places in a low-radiation environment. Despite this comment, the cumulative radiation exposure levels of the 190 subcontractor workers participating in this operation remain high.

The subcontractors are setting the workers’ annual radiation exposure limit at around 18 mSv. Of the 190 workers, five registered total radiation exposures of nearly 36 mSv (twice as high as the annual limit) in the 2014 February-September work operations alone, and these five workers will probably be unable to obtain any nuclear plant-related work next year.

Of the remaining workers, 22 have already exceeded their exposure quota for this year. Another 22 have only a small amount of quota left. This means that as many as 49 workers are currently facing the risk of losing their jobs due to excessive radiation exposure.

The question is how their jobs and income can be secured. Taking this and other problems into consideration, it is not hard to understand how difficult it will be to achieve decommissioning of the nuclear power plant.

It is TEPCO’s responsibility to protect the health and income of the nuclear plant workers who are currently engaged in challenging operations under extremely severe working conditions.

(Mikiko Watanabe, CNIC)