NISA’s Interim Report into Mihama-3 Accident Nuke Info Tokyo No. 103

The inescapable conclusion that must be drawn from the Mihama-3 accident is that the full length of the piping in nuclear power plants must be checked at regular intervals. This, however, is a conclusion that the nuclear regulators and the government want to avoid at all costs.

NISA’s Interim Report

The Nuclear and Industrial Safety Agency (NISA) released its interim report on the accident on September 27th and the Nuclear Safety Commission (NSC) released an interim report on October 21st. This article focuses on NISA’s report, with comments about NSC’s report in the ‘Further Details’ section below (FD 1,5).

NISA concludes that the maintenance guidelines (FD2) for pipes in the secondary system of Pressurized Water Reactors (PWR) are ‘generally appropriate’ and claims that data submitted by power companies indicates that, with some exceptions, thinning of pipe walls has proceeded no faster than predicted. However, a closer look at the data provided by power companies suggests that one should not place too much confidence in NISA’s sanguine assessment.

Two days after the accident NISA requested power companies to report on the status of monitoring of the thickness of pipe walls in their power plants. (Had all locations that should have been listed for inspection in fact been listed and duly inspected?) As if as an afterthought, it also requested data on the thickness of pipe walls, though there is no publicly available documentary record of this request. NISA claims to have obtained data on the thickness and the rate of thinning of pipe walls at a single point in each of 21 PWRs and 27 BWRs, as well as at 38 locations in the Mihama-3 reactor. Selection of the locations was left up to the power companies. One would not expect the power companies to provide information that incriminates them if they could avoid it, so clearly general conclusions based on this meagre data should be treated with caution.

NISA’s Recommendations

Nevertheless, NISA asserts that in the majority of cases thinning has proceeded no faster than the predicted rate and sees no reason why the exceptions should cause any problems (FD3). It concludes that the current guidelines are ‘generally appropriate’, but recommends that, just to be sure, new guidelines should be developed based on international experience and data compiled over the years. These new guidelines should be developed in a transparent manner by a neutral organization. (No mention is made of public involvement in developing the guidelines.) Standards currently being developed by the Japan Society of Mechanical Engineers (JSME) for management of pipe thickness in power plants should also be implemented when they are completed.

Investigations into the mechanism and underlying causes of the accident will continue, but some major factors have already been identified. These include quality control and communication failures by the owner of the Mihama Nuclear Power Plant, Kansai Electric Power Company (KEPCO), and its subcontractors. Measures should be taken to rectify these failures.

A final report is expected by the end of the year, but it is important to adopt measures as soon as possible to prevent a recurrence of this accident.

Comments on Interim Report

The phrase ‘generally appropriate’ (‘oumune datou/tekisetsu’ in Japanese) and other similar expressions recur throughout the report. Apparently they are used to allay any safety concerns the reader might have. In fact, they have the opposite effect, because they point to the existence of exceptions. Is not the whole purpose of the inspection regime to ensure that no pipes burst? It is not good enough to ensure that 80%, or 90%, or even 99.9% of pipes don’t burst. It only takes one burst pipe to cause a catastrophe. But the authors of the report hope to convince us that the problems are only exceptions and that by and large there is nothing much wrong with the status quo. Companies that were not directly involved in this particular accident are spared criticism. The situation in regard to Boiling Water Reactors receives scant attention, even though the problem of pipe wall thinning has begun to emerge there also, notably at the Onagawa and Fukushima-I power plants. All the blame is focused on KEPCO and its subcontractors, Mitsubishi Heavy Industries and Nihon Arm. In sum, language is used so as to confine the blame and thus limit the political fallout, so that the nuclear industry can continue to operate without suffering serious disruption.

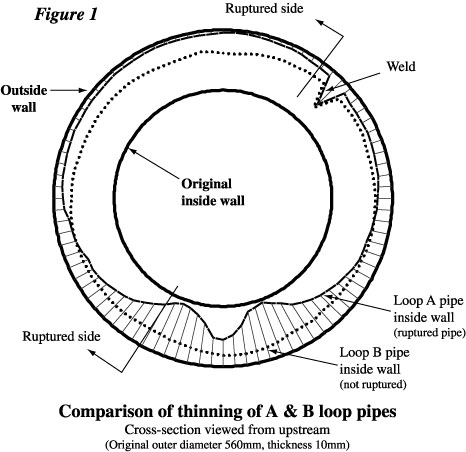

But the principles involved in the Mihama-3 accident are not so easily confined. Pipe wall thinning in nuclear reactors has occurred at varying rates over time, at varying rates for identical pipes, and even at varying rates for different points around the diameter of a single location (figure 1). Despite all the research that has been carried out in order to elucidate the mechanism of the erosion/corrosion process (FD4), which is thought to be the culprit in this case, the mechanism involved is still not fully understood. A predicted rate of thinning is used when determining the life expectancy of pipes, but this rate has no scientific basis. There are plenty of exceptions, but these are said to fall within the range of error, or are discounted altogether. Under these circumstances it is impossible to claim that any location is safe unless it has been checked recently. NISA has been forced to accept that there are variations in the rate of pipe wall thinning and that the phenomenon of localized thinning is a problem for the inspection regime. The data leaves it with no choice. But it refuses to draw the logical conclusion – that the full length of the piping must be inspected regularly.

Other than its recognition of localized thinning, the interim report contains one other important recognition. It plainly states that since one role of the secondary system is to remove heat produced by the reactor, from the point of view of safety it is necessary to recognize that the primary and secondary systems are part of a total system. This would seem to be obvious, but since the low priority given to the secondary system was one factor leading to the Mihama-3 accident, it is important that this historical neglect be reversed. One wonders, however, whether the message has got through to KEPCO. The General Manager is reported to have said that the accident was just a workers’ compensation case. Clearly he didn’t see the connection with reactor safety.

The other outstanding feature of NISA’s report is its studied avoidance of self-criticism. NISA and its parent body the Ministry of Economy, Trade and Industry (METI – formerly MITI) were responsible for approving the original licenses for all nuclear power plants. In approving these licenses they share blame with regulators throughout the world for failing to recognize the problem of erosion/corrosion-induced thinning. Then when this problem came to light, particularly after the 1986 Surry accident, they claimed that accidents such as this couldn’t happen in Japan. It was they who established the regulatory regime and they were the ones who supposedly checked that inspections were carried out properly. However nothing about their errors of judgment, their complacency and their regulatory failures appears in the interim report.

The interim report speaks of the need for NISA to remind the power companies of their responsibilities and to confirm that they are doing the right thing, but the focus is on what the power companies, particularly KEPCO, ought to do, rather than on what NISA ought to do. The things that the power companies ought to do mostly relate to quality control. They are things that they were already required to do, either legally, or as a common sense corollary of their legal obligations. Indeed, as recently as May this year NISA approved an amendment to the Mihama-3 license that included obligations which KEPCO failed to fulfill. In this regard, the interim report refers specifically to the issue of management of the subcontracting process. All this begs the question: what guarantee is there that the power companies will fulfill their obligations any better in future and why should we believe that NISA’s oversight will be any more effective than it was in the past?

Conclusion

Perhaps all the references to the things that NISA needs to ‘confirm’ (‘kakunin’ in Japanese) can be interpreted as a tacit admission that it failed to confirm these things in the past. If so, we would prefer that NISA admitted its failure more directly. However, to expect direct admissions of failure would be to misunderstand the process. This interim report is not about getting to the bottom of the Mihama-3 accident. It is about political damage control. NISA will remain steadfast and true to its principal mission, which is to keep the nuclear industry going. Admissions of failure would not serve this purpose, so NISA will not provide any. Nor will it recommend measures that would make nuclear energy prohibitively expensive, so most of the piping in nuclear power plants will remain unchecked.

To us all this is plainly ludicrous. The challenge is to make more and more people aware of this fact. Perhaps when NISA and the nuclear industry become a public laughing stock, we will be well on the way to eliminating nuclear energy. However this may be, CNIC and others are holding meetings with NISA in order to get to the bottom of the matter and to ensure that superficial reports are exposed for what they are.

Philip White (NIT Editor)

Some Further Details

FD 1 After the accident NISA convened the Mihama Nuclear Power Plant, No. 3 Reactor, Secondary System Pipe Rupture Accident Investigation Committee (our translation). NSC convened another committee with a name barely distinguishable from that of the NISA committee and both committees have now produced interim reports. NSC’s report basically assesses the appropriateness of the findings of NISA’s report, so we will only comment on points where they add something or are critical of NISA’s report (see TD 5). In addition to these two committees, NISA also requested the Japan Atomic Energy Research Institute (JAERI) and Japan Nuclear Energy Safety Organization (JNES) to investigate the mechanism involved in this accident. Some of their findings are included in NISA’s interim report and they are still following up other issues. The Fukui Police are also investigating the accident to see if charges should be laid, so presumably a report will come out of that process too.

FD 2 The current maintenance system for PWR secondary system pipes is based on guidelines introduced in May 1990. Originally, inspections covered by these guidelines were ‘voluntary’, but they were made mandatory under the Electric Utilities Industry Law in October last year. These guidelines distinguish: (a) key locations, which require regular checks; (b) locations which may be checked on a ‘sampling’ basis; and (c) locations which don’t need to be checked at all. Those locations checked on a ‘sampling’ basis should be checked at a rate of 25% of the total area over a period of 10 years. This means that some locations listed for sampling might not be checked for 40 years. The method by which the thickness of pipe walls should be measured is not specified, but in practice four to eight points on a given cross section of pipe are subjected to ultrasound checks. Where measurements indicate that pipe walls are thin enough to be of concern, more detailed checks are carried out around that location. NISA’s interim report recommends that, in the course of revising the guidelines, the method by which these measurements are carried out should be included.

FD 3 NISA’s reasoning is as follows:

An initial rate of thinning is set. For locations that are checked regularly this rate and the predicted life expectancy of the pipe can be revised if the first check, or subsequent checks reveal that actual thinning is proceeding at a faster rate. As long as checks are scheduled with sufficient leeway and pipes are fixed or replaced as necessary, no safety problems should arise. Indeed, in the case of the Mihama-3 accident, subsequent calculations show that the actual rate of thinning was very close to the predicted rate (0.47×10-4 compared to 0.45×10-4 mm/hour, based on a minimum thickness of 0.6 mm at the time of rupture). The problem in this case was not that the predicted rate of thinning was wrong. It was rather that the pipe was never checked. For locations checked on a sampling basis, NISA takes that view that where necessary the schedule can be brought forward. NISA also concedes that it might be necessary to add some extra locations to the list of locations subject to regular checks, but nowhere do they acknowledge that sampling per se is an inappropriate method.

FD 4 Erosion/corrosion has been identified as the process that weakened the pipe which burst at Mihama-3. Evidence for this includes the scaly appearance of the interior of the burst pipe, the location of the rupture just downstream from a turbulence-inducing fixture (‘orifice’ – see NIT 102), and the fact that the temperature of the pressurized water at the point of rupture (around 1400C) was within the range where erosion/corrosion typically occurs. The pipe involved in the Mihama-3 accident was a carbon steel alloy. It is well known that these pipes are prone to erosion/corrosion. Although the mechanism has not been fully described, in broad terms the process is well known. In the first place a layer of metal oxide forms on the inside of the pipe. Because this layer is chemically inert it protects the underlying metal from corrosion, but erosion of this layer can be exacerbated by such things as turbulent flow. Once the surface has been eroded, corrosion proceeds until a new layer of metal oxide forms. The pipe gradually thins as this process is repeated over and over again.

The ruptured pipe at Mihama-3 was just 0.4 mm at the thinnest place. Allowing for stretching, it might have been a little thicker at the time of rupture. However, considering that the regulatory limit is 4.7 mm, it is no surprise that a pipe this thin and under 10 atmospheres pressure should burst. Nevertheless, we wonder whether there might not have been some other catalyst. Was there any manipulation or mechanical fault that triggered the accident, right at the time when preparations were being made for a periodic inspection? The interim report provides no clues to help answer this question.

FD5 Some findings from NSC’s interim report:

The mechanism of the pipe rupture is not yet understood, so investigations into this matter should continue.

Did pipe wall thinning alone really cause the accident with no other trigger mechanism? The sequence leading from pipe thinning to rupture should be clarified.

NISA concluded that failure to monitor pipe thickness was the direct cause of the accident, but the sequence of events which caused this failure needs to be clarified.

NSC believes in an audit approach to regulation. It believes that confirming the effectiveness of the company’s own quality control system is more important than strengthening regulations and confirming compliance with standards.

Our response to these recommendations is that, even where they are desirable in themselves, we doubt whether some of them are achievable. In the end we conclude that ensuring the safety of nuclear power plants is actually an impossible task.