Restarting Monju – Like Playing Russian Roulette Nuke Info Tokyo No. 134

Japan’s Monju Prototype Fast Breeder Reactor (FBR, 280MWe) is scheduled to restart by the end of the 2009 fiscal year (March 31, 2010). If it does so, it will be the first time the plant has operated since it was shut down as a result of a sodium leak and fire fourteen years ago. This article reviews the history and current status of Monju and Japan’s FBR program.

Japan’s Monju Prototype Fast Breeder Reactor (FBR, 280MWe) is scheduled to restart by the end of the 2009 fiscal year (March 31, 2010). If it does so, it will be the first time the plant has operated since it was shut down as a result of a sodium leak and fire fourteen years ago. This article reviews the history and current status of Monju and Japan’s FBR program.

The sodium accident

On December 8, 1995 at 19:47 an alarm went off indicating high sodium temperature at the exit of the intermediate heat exchanger in C-loop of Monju’s secondary coolant system. One minute later an alarm sounded indicating a sodium leak. At 19:52 staff confirmed that white fumes were coming from the area near the alarm sensors. The reactor was tripped manually at 21:20. Draining of sodium out of C-loop was started at 22:40 and completed at 0:15 on December 9. In other words, the operators waited for about an hour and a half before stopping the reactor and nearly three hours before taking action to stop the leak. (See NIT 51.)

The leaked sodium reacted with the air in secondary coolant piping room C, causing a spray-fire and filling the room with fumes. It melted scaffolding and a ventilation duct and damaged the floor’s steel liner. According to official reports, the temperature of the steel liner reached 700oC~750oC. Had the sodium melted through the metal liner and come in contact with the concrete below, the accident would have been even more serious. It was eventually estimated that about 640 kilograms of sodium leaked into the piping room.

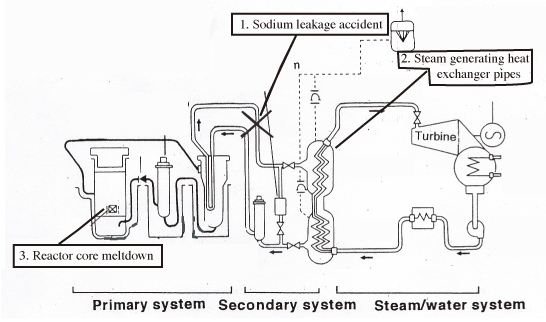

The Monju reactor is cooled by molten sodium flowing through a three-loop primary system. Heat from the primary loops is transferred to secondary loops, which are also filled with sodium. Heat from the secondary system is then transferred via steam generators to the tertiary system to produce steam to drive the turbines (see figure 1). Since sodium reacts explosively with water, it is essential that sodium not come into contact with the water and steam in the tertiary system. Cracks and holes in the steam generator pipes must be prevented at all costs.

| Figure 1 |

|

The direct cause of the accident was a broken thermocouple in a pipe in the secondary system. Sodium leaked through the aperture that was created. The thermocouple sheath broke as a result of metal (high-cycle) fatigue from vibration caused by the sodium flow. It was finally recovered over four months later 160m downstream from its original location. The thermocouple, manufactured by Ishikawajima-Harima Heavy Industries (IHI), suffered from a fatal design error. The angular structure of the section that penetrated the pipe (seefigure 2) meant that it was exposed to resonant vibration caused by a symmetrical vortex in the sodium flow. It is suspected that it was already cracked at least six months and perhaps as long as two years before the accident. It could be said, therefore, that this was an accident waiting to happen.

Besides the direct technical cause, it is possible to identify institutional and policy failures that created an environment in which such accidents were bound to happen. CNIC organized a Monju Committee to make an overall assessment of the accident from technological, legal/institutional and policy perspectives. The Monju Committee pointed out that the rules governing the Monju project as a whole made it virtually impossible to check in advance for design flaws. It also noted that the manual for dealing with accidents was flawed in that portions of it contradicted the original safety review for licensing. More fundamentally, with respect to the government’s plutonium policy the report said that no lessons were learned from fast breeder development in other countries and that the accident may well have been caused by the high priority placed on getting Monju operational as quickly as possible. The report called for a thorough reconsideration of the underlying assumption of the government’s plutonium policy, namely that breeding plutonium is an effective way of addressing Japan’s future energy needs.

The official review process was flawed from the beginning. The initial investigations were carried out by Monju’s owner and operator, Power Reactor and Nuclear Fuel Development Corporation (PNC)1. PNC’s controlling agency, the Science and Technology Agency (STA)2 also carried out an investigation, as did the Nuclear Safety Commission (NSC). However, these reports lacked objectivity and provided minimal information to the public. It was only as a result of massive public pressure that STA gradually became more willing to release information. The Monju accident triggered an outburst of dissatisfaction with the government’s handling of nuclear power development. On January 23, 1996 the governors of Fukui, Fukushima and Niigata Prefectures3 issued a joint statement (see NIT 52) and resolutions were adopted by over two hundred local and prefectural assemblies. The resolutions called either for the decommissioning of Monju, or for a reassessment of its development plan.

| Figure 2 |

|

PNC initially attempted to cover up the seriousness of the accident. Video footage was released immediately after the accident, but it was later discovered that this one-minute tape was an edited version of two original videos, which PNC judged too shocking to release. The edited version only showed a lump of sodium product in a corner of the room, while all other pipes and structures appeared to be intact. The longer versions showed serious damage to the pipes and ducts, as well as large amounts of sodium product spread all around.

An in-house team was tasked with looking into the cover-up, but the investigation took a tragic turn on January 13, 1996, when one of the team leaders, Shigeo Nishimura, deputy general manager of PNC’s general affairs department, jumped to his death from a hotel in Tokyo. His widow, Toshiko, has been pursuing justice for her deceased husband ever since, suing PNC for failing in its duty of care. She appealed to the Supreme Court after the Tokyo High Court rejected her case on October 29, 2009.

History of Monju and its place in Japan’s FBR program

Construction of Monju began in May 1986. It first achieved criticality on April 5, 1994 and was temporarily connected to the grid on August 29, 1995. At the time of the accident Monju was undergoing tests at 40% power output in preparation for full operation.

Prior to Monju, the Joyo experimental FBR in Oarai, Ibaraki Prefecture first achieved criticality on April 24, 1977. Joyo Mark-I had a thermal output of 50 MWt, but after a series of upgrades the current Mark-III core has a thermal output of 140 MWt. Like Monju, Joyo uses mixed plutonium-uranium oxide (MOX) fuel and sodium coolant. The JCO criticality accident, Japan’s worst nuclear accident, occurred while preparing uranium enriched to 18.8% for Joyo Mark-II. Joyo has been shut down since June 2007, when machinery in the upper part of the core was damaged while extracting experimental equipment. The original problem and the difficulty fixing it both arose from the fact that it is impossible to see inside sodium-cooled reactors. Sodium coolant, unlike water coolant used in light water reactors, is not transparent.

Japan’s first Long-Term Plan for Research, Development and Utilization of Nuclear Energy, approved in 1956, adopted the following policy on breeder reactors:

“In regard to Japan’s future research, development and utilization of nuclear energy, principally from the perspective of effective utilization of nuclear fuel resources, since breeder type power reactors are thought to be the most suited to Japan’s national conditions, an objective of national production of [this type of reactor] is adopted.” (CNIC translation)

The Long-Term Plan has been revised approximately every five years since then, but the basic FBR policy established in the 1956 plan has not changed. By contrast, the estimated time required for the commercialization of FBRs has changed greatly. The 1961 Long-Term Plan was wildly optimistic in its estimate of when FBRs would become commercially viable, predicting that they would be in use sometime around 1980. As explained below, the target date for commercialization of fast breeder reactors is now 2050, seventy years behind the original schedule.

Continuation of the FBR program and of Monju has been endorsed repeatedly since the Monju accident. In 1997 a committee was established within the Atomic Energy Commission (AEC) to review the FBR program and in December 1997 AEC determined that FBR development should continue. AEC’s latest Long-Term Plan, approved in 2005 under the title Framework for Nuclear Energy Policy, states that the aims of restarting operations at Monju are “demonstrating reliability as an operational power plant and establishing sodium handling technology”. The aim is to achieve these goals within approximately 10 years and then make Monju a center for international cooperation.

In March 2006, the Japan Atomic Energy Agency (JAEA) released the final report of Phase II of its “Feasibility Study on Commercialization of the Fast Breeder Reactor Cycle Systems” (NIT 112). The Feasibility Study essentially endorsed the basic concepts of the Monju prototype FBR for the future commercialization of FBR. It selected sodium coolant, oxide fuel and aqueous reprocessing as its “main concept” and assumed that future technical development would enable scaling up and incorporation of minor actinides in the fuel.

The Nuclear Energy Subcommittee of the Advisory Committee for Natural Resources and Energy, in its August 2006 Nuclear Power Nation Plan, proposed that “a vision of the commercial FBR cycle” and “a research and development program for the commercialization of FBR technology” be developed by around 2015. It proposed target dates of 2025 for realization of a demonstration FBR and 2050 for introduction of FBRs on a commercial basis. No indication was given of what organization will take the lead in constructing the demonstration reactor, or of the relative degree of involvement of government and private enterprise.

In the absence of any clear plan for a demonstration reactor, the fixation with Monju continues, even though there are no prospects of commercializing this design. Evidently the original intention of positioning Monju as a breeder reactor has been abandoned. A different design has been proposed for the demonstration reactor. Proposed changes include a cost against safety tradeoff whereby the number of coolant loops will be reduced from three to two.

Obstacles and delays

On January 27, 2003 the Nagoya High Court’s Kanazawa branch handed down a historic ruling nullifying the government’s 1983 permission for construction of Monju. The verdict recognized three main areas in which the Nuclear Safety Commission’s (NSC) pre-construction safety review was inadequate.

- In light of inadequacies in the design of the steel floor liner, which became evident as a result the Monju accident, the Court accepted that the radioactive substances in the nuclear reactor container could be released into the environment in a situation where the secondary cooling system ceased to function.

- The Court recognized that NSC’s safety review did not fully address preventive measures against simultaneous rupture of steam generator tubes, where the rupture of one tube triggers ruptures in peripheral tubes under high temperatures.

- The Court concluded that NSC’s analysis was inadequate in relation to prevention of core meltdown.

On May 30, 2005 the Supreme Court reversed the Nagoya High Court decision on the narrow grounds that NSC’s safety assessment was “not unreasonable” and that it did not “contain flaws that could not be overlooked”. However, the Supreme Court did not say that Monju was safe to operate.

Shortly before the Supreme Court verdict, on February 7, 2005, Fukui Governor, Issei Nishikawa, granted approval for the start of modifications to Monju. The modifications began on September 1, 2005 after the reactor had been shut down for nearly ten years and were completed on August 30, 2007. Modifications included the following: removal and replacement of the temperature gauge that was the cause of the accident; modification of the sodium drainage system; installation of insulation on walls and ceilings, nitrogen gas infusion apparatus, and a comprehensive video monitoring system; and measures to deal with a water-sodium reaction accident arising from a water leak from the steam generator heat transfer tubes. These measures mainly relate to sodium, but other dangers inherent to the Monju design, including the possibility of a run-away chain reaction and problems related to seismic safety, remain unchanged.

The danger of a loss of control over reactivity leading to collapse of the reactor core is much greater in FBRs than in light water reactors (LWR). FBR fuel assemblies are packed much more densely than in LWRs. If the fuel assemblies bend for any reason, the distance between them is reduced even further, increasing core reactivity and creating the risk of a runaway chain reaction and core melt down. FBRs of Monju class and larger have the additional weakness of a “positive void”, meaning that if bubbles form in the coolant, core reactivity tends to increase. Although not an FBR, a positive void was instrumental in causing the 1986 Chernobyl accident. Both these weaknesses could come into play if a loss of electric power caused the primary coolant pumps to stop working.

In regard to seismic safety, there are problems with the design of Monju’s piping system. To cope with sudden temperature changes due to the high heat conductivity of sodium, Monju’s piping is much thinner than in light water reactors. Also, it is not fixed and it is not straight. Instead, it winds around above the reactor. This represents a very real danger in earthquake-prone Japan, especially given that the Headquarters for Earthquake Research Promotion discovered a previously unknown active fault. The Urasoko fault connects with the Yanagaseyama fault on the ocean floor of Tsuruga Bay, with the latter extending to Shiga Prefecture. The seismic safety assessment is now being redone by a subcommittee of the Nuclear Industrial and Safety Agency (NISA).

The original target date for restart was February 2008, but this date has been delayed on four occasions. The main reasons for the delay are JAEA’s inability to rectify problems with its sodium leak detectors, corrosion in the exhaust duct and the need to replace degraded fuel. The leak detectors have gone off repeatedly in various locations, even though there was no sodium leak. The exhaust duct had not been inspected for ten years, because no inspection plan had been prepared. The problem with the fuel was that since it was first fabricated over half of the original “fissile” plutonium-241 had decayed into americium-241. In order for Monju to reach criticality, new fuel assemblies had to be fabricated.

Recent developments

On December 8, 2009 JAEA announced its schedule for performance testing leading to full operation of Monju. The tests are scheduled to begin by the end of March 2010 and will be conducted over a period of three years in the following three phases: reactor core confirmation tests, plant confirmation tests at 40% power, tests raising power output. If the tests proceed according to plan, Monju will begin full operations by the end of March 2013.

After carrying out four special safety inspections from May 2008 to March 2009, on April 22, 2009 NISA finally reported to the Advisory Committee for Natural Resources and Energy’s Investigation Committee for Confirmation of the Safety of Monju that an independent quality control system had begun to operate. However, the overall structure has not changed and it is unclear from NISA’s report how the organizational reforms will solve the problems. Monju is owned by JAEA, but it is managed in cooperation with the nuclear power companies and major plant makers Mitsubishi Heavy Industries, Toshiba and Hitachi. Below these there are numerous subcontractors and sub-subcontractors. The channels of communication between top and bottom of the chain were not operating effectively and morale was very low.

On July 14, 2009 84 fuel assemblies and 19 control rods were replaced. Then on August 12 a 141-point plant confirmation test was completed. The same day JAEA announced that it planned to restart the plant by the end of the 2009 fiscal year. No doubt there were political considerations behind the announcement. JAEA needed to indicate that it would restart Monju in FY2009 in order to secure its FY2010 budget allocation for Monju. There was a change of government shortly after the announcement and the new government is seeking areas where it can cut spending.

According to JAEA, another reason for the target start-up date was that seismic safety improvements would take until the end of November to complete. However, the logical thing would have been to wait for NISA to complete its seismic safety checks before commencing seismic safety improvements, especially considering that Monju had not yet commenced full operations when the sodium accident occurred. When Monju was first constructed the design base ground motion for an “extreme design earthquake” (S2) was set at 450 Gal. Revised seismic design guidelines published in September 2006 established a new design base ground motion, Ss. At first, Ss for Monju was set at 600 Gal, but after consideration by NISA it was raised to 760 Gal. Confirmation of seismic safety based on this figure has not been completed.

Problems continue with the sodium leak detectors. On October 7, 2009 the electric power supply was switched off in order to check the leak detectors, but at the same time the power supply to the equipment for measuring the sodium level in the reactor was switched off. This caused another false alarm. The fact that the power supply for both items of equipment was connected had not previously been noticed. Then on October 23 the pumps for sodium leak detectors in both the primary and secondary circuits went down. As a result, the detectors were out of action for one hour and fifteen minutes. JAEA is trying to get an exemption from the requirement that false alarms during inspections be reported. So far NISA has not approved such an exemption. Nor should it. Such an exemption would create a dangerous grey zone. The fact that JAEA has the audacity to ask for such an exemption is a problem in itself.

Cost without benefit

Documents published by the new government’s Administrative Reform Council, which was established to identify wasteful projects, show that up to and including FY2009 the government has spent over 900 billion yen on construction and maintenance of Monju. Of this 230 billion yen represents maintenance costs since the accident. This does not include other FBR-related research and development.

Monju’s fuel was not removed after the accident, remaining submerged in sodium. Circulation of sodium was maintained in the three loops of the primary system and in one of the three secondary loops. The other two secondary loops were filled with argon gas. Electric motors have continued to pump sodium, electrically heated to 200oC, through the pipes. The need to keep the molten sodium circulating means that Monju has continued to consume a large quantity of electricity. CNIC obtained details of electricity consumption for the 2004 fiscal year. In that year_ Hokuriku Electric Power Company was contracted to provide 70,127,000 kWh at a price of 695,572,563 yen. In fact, the final consumption for that year was only 58,533,960 kWh, but being a fixed price contract, the price did not change.

On November 11 a working group of the Administrative Reform Council recommended that Monju be allowed to restart, but that the rest of the FBR program should be frozen while the respective responsibilities and roles of METI and MEXT are sorted out. However, in the new government’s draft budget for the 2010 fiscal year 23.3 billion yen is allocated for Monju (an increase of 2.9 billion yen compared to 2009), while 37 billion yen is allocated for FBR related research (1.4 billion yen less that the original budget request, but still an increase of 2.3 billion yen compared to 2009.)

International context

It is a great irony that the first nuclear reactor to generate electricity was a FBR. The Idaho National Laboratory’s EBR-I generated a tiny amount of electricity in 1951, but in 1955 it suffered a runaway chain reaction resulting in a partial core meltdown. FBRs have been plagued by cost, safety and proliferation problems ever since. Nevertheless, the dream of a virtually inexhaustible source of energy still mesmerizes some, while the counter-intuitive theory that these reactors might help solve the problem of radioactive waste has taken on a life of its own in recent years. Besides Japan, there is still political support of some sort or other for fast reactor development in countries including the US, France, Russia, China and India, although the degree and nature of the support varies from country to country.

The US withdrew from FBR development in response to India’s 1974 nuclear test. In 1977 the Carter Administration froze the US’s commercial plutonium use program, including FBR, on non-proliferation grounds. Congress stopped funding for the Clinch River FBR project in 1983 and finally halted the FBR program altogether in 1994. The idea of fast reactors made a come back in February 2006 under the Bush Administration’s Global Nuclear Energy Partnership (GNEP). However, the focus was no longer on breeding plutonium, which was still seen as a proliferation risk, but rather on burning surplus plutonium and minor actinides to reduce the radioactive waste burden. The pendulum swung back the other way again in June 2009, when the Obama Administration cancelled the program to develop spent nuclear fuel reprocessing and fast reactor technologies in cooperation with other countries. GNEP’s domestic research and development initiative was retained, but the aim is no longer to develop near-term commercial projects. Instead the focus is on long-term R&D on advanced reprocessing and fast-reactor technologies.

France achieved criticality with its first FBR, Rapsodie, in 1967 and connected the demonstration FBR Superphenix (at 1,200 MWe the world’s largest FBR ever built) to the grid in 1986. However, the 1991 nuclear waste law shifted the focus of Superphenix from breeding plutonium to transmuting surplus plutonium and minor actinides into shorter-lived isotopes as a radioactive waste management strategy. In 1998 Superphenix was finally closed down permanently. With a cumulative load factor of just 7.79% it had proved to be a costly white elephant. France’s Phenix fast reactor, first connected to the grid in 1973, was finally disconnected in March 2009. A ceremony to mark the end of operation was held on September 12, 2009.

The US and France now face practical problems if they want to develop fast reactors. The US has been out of the business for so long that it has a skill shortage, while France no longer has a fast reactor to carry out transmutation tests. They are therefore looking to Japan for support. In August 2009 France, Japan and the US amended an earlier agreement to cooperate on sodium-cooled fast reactor research and development. One focus is to determine whether Monju could be used for international transmutation research. If Monju is restarted, the three countries plan to use it to carry out an irradiation program in the framework of the Generation IV International Forum.

Russia and China have FBR programs, although they are significantly different from Japan’s program. Russia’s BN-600 reactor (Beloyarsk-3), which was connected to the grid in 1980, uses chiefly uranium dioxide fuel with an enrichment of 17-26%. It is probably the only fast reactor in the world still generating electricity, unless the Indian fast breeder test reactor at Kalpakkam is still generating a tiny amount of electricity. BN-600 is not well suited to a breeder program, but Russia is currently constructing a BN-800 demonstration FBR (Beloyarsk-4), which can use MOX fuel and might be used to breed plutonium. Start-up of Beloyarsk-4 is currently scheduled for 2014, two years later than originally planned.

China’s FBR program is based on Russia’s. In October 2009 China and Russia signed an agreement to start pre-project and design works for two BN-800 reactors in China. Russia and China are already cooperating on one fast reactor, a small 65 MWt sodium-cooled unit known as the Chinese Experimental Fast Reactor at the China Institute of Atomic Energy near Beijing.

India is constructing a 500 MWe prototype FBR at Kalpakkam. However, it is important to remember that the Indian program is not “peaceful”. In 2008 the Nuclear Suppliers Group made a special exception to its rules to allow nuclear trade with India. In return, India agreed to place more of its nuclear facilities under International Atomic Energy Agency (IAEA) safeguards, but India’s FBRs were not included in the list of “civilian” facilities submitted to the IAEA. They are officially military facilities and India is still producing fissile material for weapons use. Therefore, Japan would be wise not to point to India as evidence that it is not alone in pursuing a plutonium-breeding program.

Conclusions

Monju shares the same problems of nuclear proliferation, safety and cost that have plagued fast breeder reactors in other countries. There is no sign that the benefits that are supposed to compensate for these dangers, namely breeding of plutonium as an inexhaustible civilian energy source and transmutation of radioactive waste, will ever be viable. The Japanese government will try to trumpet the value of Monju for international transmutation research, but it is highly unlikely that Monju will be used as a breeder reactor.

Japan’s fuel cycle program, of which Monju is a key part, represents a serious nuclear proliferation problem. The rationale for Japan separating plutonium from spent nuclear fuel was to supply its FBR program, but there were warnings from all around the world about the massive stockpile of surplus plutonium that Japan would accumulate in the process. (See for example an article in NIT 20, Nov./Dec. 1990 by Jinzaburo Takagi entitled “Plutonium: 50 Years on”.) These warnings were proved correct. Japan now has about 47 tons of separated plutonium, nearly 10 tons of which is stockpiled in Japan. The rest is held in France and the UK. Regardless of Japan’s own intentions, this plutonium stockpile sets a bad example for other would-be nuclear proliferators.

From a safety perspective, if anything the danger of operating Monju is even greater than it was before the sodium accident. During the fourteen years that Monju has been sitting idle, pipes and equipment would have degraded. However, it is impossible to check for cracks and holes throughout the whole plant, especially where sodium prevents visual inspection. Furthermore, JAEA’s attitude has not changed. Its instinct is still to cover up problems, as evidenced by its proposal not to report false alarms of sodium leaks. The condition of the plant and the nature of the operator both suggest that more trouble lies ahead. To restart Monju now would be like playing Russian roulette.

Regarding cost, Monju is one of Japan’s most wasteful projects. If the government is serious about redirecting taxpayers’ money to where it is most needed, it should not wait for further troubles to arise before withdrawing support for Monju and the FBR program.

By Philip White (NIT editor) and Hideyuki Ban (CNIC Co-Director)

Notes and references

1. Plagued by problems, PNC subsequently changed its name to Japan Nuclear Fuel Cycle Development Institute (JNC). JNC later merged with the Japan Atomic Energy Research Institute (JAERI) to form the Japan Atomic Energy Agency (JAEA), which is now under the auspices of the Ministry of Education, Culture, Sports, Science and Technology (MEXT).

2. STA was headed by a Cabinet Minister, but government ministries were restructured on January 6, 2000. STA’s R&D role was transferred to the JNC later merged with the Japan Atomic Energy Research Institute (JAERI) to form the Japan Atomic Energy Agency (JAEA), which is now under the auspices of theMinistry of Education, Culture, Sports, Science and Technology (MEXT) and its regulatory role was transferred to the Nuclear Industrial and Safety Agency (NISA) within the Ministry of Economy, Trade and Industry (METI).

3. These three prefectures are home to the overwhelming majority of Japan’s nuclear power plants. Monju is located in Tsuruga City in Fukui Prefecture.

4. Sources include the following:

Past editions of Nuke Info Tokyo and CNIC’s Japanese newsletter.

“Fast Breeder Reactors Will Never Be Put to Practical Use” (Japanese Document): Paper presented at a public meeting hosted by CNIC on December 8, 2009, the 14th anniversary of the Monju accident, by Keiji Kobayashi, formerly an instructor at Kyoto University Research Reactor Institute.