Final Reports on Mihama-3 Accident: Critical Facts Remain Unclear Nuke Info Tokyo No. 106

1. What was the Mihama-3 accident?

Nearly a year has passed since a pipe ruptured in the secondary system of Kansai Electric Power Company’s (KEPCO) Mihama-3 reactor (PWR, 826 MW, commenced operation 1976). The accident occurred on 9 August 2004 and the resulting steam leak killed five workers and seriously injured six others (see NIT 102 and 103 for details).

2. Official Investigations

(a) In August an investigation committee was set up under the auspices of the Nuclear and Industrial Safety Subcommittee of the Advisory Committee for Natural Resources and Energy. The Nuclear and Industrial Safety Agency (NISA) provided the secretariat. All these organizations come under the Ministry of Economy Trade and Industry (METI). This investigation committee delivered an interim report on 27 September 2004. It met ten times and was disbanded after handing down a final report on 30 March 2005.

(b) Two companies which were directly involved, KEPCO and Mitsubishi Heavy Industries (MHI), submitted reports to NISA on March 1st. A third company, Nihon Arm Co. Ltd., was not requested to submit a report.

(c) In August another investigation committee was set up under the auspices of the Nuclear Safety Commission (NSC). This committee delivered an interim report on 20 October 2004. It met eleven times and was disbanded after handing down a final report on 22 April 2005. It is fair to think of this as a rubber stamp to the NISA report.

(d) The Fukui Prefecture Police Department carried out several searches of KEPCO’s Wakasa branch office and the Mihama Power Plant. However, it didn’t search the head office in Osaka. At this stage, no KEPCO employees have been charged.

3. Explanation of the accident

NISA confirmed KEPCO’s account that the accident was caused by erosion corrosion of the carbon steel pipe, downstream from an ‘orifice’. The presumed reason why this was so pronounced in the A loop, compared to the B loop pipe, was that strong whirling currents occurred at the header where the A loop pipe branched off from the main condensate pipe. (This theory is based on experiments on a miniature scale and on computer analysis.) The loss of water is estimated to have been 885 tons.

KEPCO reported that it could have reduced the loss of water, but NISA doubted that reducing the loss of water would have had any effect on rescue operations.

As reported in NIT 102, valves in the auxiliary feedwater pump failed to open. KEPCO believes the cause to be that the pressure downstream exceeded the pressure upstream of these valves. It says it will replace the valve springs with stronger ones. This was a very primitive design error.

The fact that steam entered the central control room (figure 1), next door to the turbine building was not revealed publicly until December. KEPCO reported this to Fukui Prefecture in December and the NISA investigation committee published the information in March 2005. However KEPCO already knew this on the day of the accident. The fact was reported to NISA in October 2004. KEPCO believes this occurred because of the inadequacy of seals around cables leading into the control room. NISA has ordered checks of valves and seals at all other power plants.

4. Failure to include pipes on the inspection list

The secondary system was subject to operator inspections. (After 2003 these became ‘periodic operator’ inspections.) The maintenance of pipes was carried out under guidelines after 1990, but these guidelines actually resulted in a reduction in the number of inspections (figure 2). Under the guidelines, the area downstream of orifices (the location of the rupture) was subject to monitoring of the remaining life of the pipe, but MHI failed to include the part in question on the list. In MHI’s March 1st report it stated that it believed the causes of this were excessive reliance on veteran staff, changes to a large quantity of skeleton diagrams, and monotonous repetitive work. None of the reports explain why the same omission at Tomari-1 (Hokkaido Electric), Tsuruga-2 (Japan Atomic Power Company (JAPCO)), Takahama-4 (KEPCO) and Mihama-1 (KEPCO) was rectified and the location checked, but not at Mihama-3.

KEPCO made the new claim in its March 1st report (without providing any evidence to back it up) that after the pipe thinning problem was discovered at Ohi-1 (July 2004) it noticed that the location of the Mihama-3 accident had not been inspected. The NISA and NSC reports both fail to answer the questions of when KEPCO became aware that the pipe had not been inspected, when it became aware that some locations had not been included on the inspection list, and whether remaining life expectancy assessments had been made. Given that these were fatal lapses, people have every right to expect a full, honest and comprehensible account of the accident.

5. Operator management of pipes

Pipes less than the minimum necessary thickness are non-compliant with the technical standards. KEPCO and NISA report that at each of the Mihama, Ohi and Takahama plants reactors were operated with pipes which had been assessed as having less than one year’s life left, or with pipes that were assessed as being below the regulation thickness. These pipes were not changed at periodic inspections, despite these assessments.

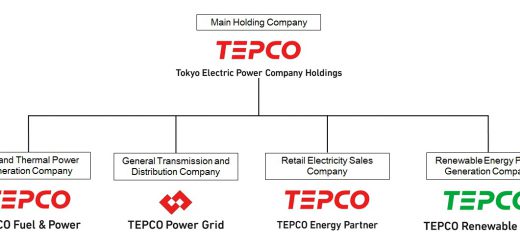

NISA also noted that other power companies (Hokkaido, Kyushu, Tokyo, JAPCO) had postponed changing pipes. Something that is not mentioned in NISA’s report is the fact that other companies, including Tokyo Electric Power Company (TEPCO) and Tohoko Electric Power Company, measured pipe thicknesses at the straight part of pipes near elbows and recorded these as measurements of elbows, even though the elbows were never actually measured.

The Mihama-3 accident was a corollary of this informal, self-controlled system of pipe management.

6. Future management of piping

Japan Society of Mechanical Engineering is in the process of drafting standards for management of pipe thinning. These are scheduled to be ready in September and they will be adopted as administrative standards. (JSME’s standards are civil standards, but they will be used as governmental standards.) On 18 February 2005 NISA issued a notice to power companies regarding requirements for management of the thickness of pipes at nuclear power plants for the period until JSME’s standards are ready. Each power company may be revising their own pipe management guidelines, but since no information has been made public, the situation might not have changed at all. The first step should be to make public the current situation.

7. Future system of inspection of nuclear power plants

On March 22nd Fukui Prefecture’s Nuclear Safety Experts’ Committee demanded that NISA include the following in its final report: “clarification of the government’s involvement and responsibility in the pipe management system” and “the fact that ‘hard-side’ safety measures and safety regulations are the basis [of nuclear safety]”. However, NISA states in its report that it will “also make companies’ thorough performance of ‘soft-side’ safety assurance activities the object of safety regulations” and “aim to increase companies’ independent maintenance management capability for the plant as a whole.”

The preventative plan submitted by KEPCO to the investigation committee in March only addressed organizational management issues. At the time, KEPCO’s President intended to continue in his post. Given that his management was part of the problem, the plan was fundamentally flawed from the start. In the face of strong criticism, he has now agreed to resign his post of President at the end of June. On March 28th KEPCO released a management efficiency plan, which probably reflects its true intentions. It states, “The management environment facing the company will become more severe…We will aim for a long-term reduction in costs through efficiencies in facility maintenance, brought about by a review of the time between inspections and the scope of maintenance work.”

In December 2004 another committee was established within the Nuclear and Industrial Safety Subcommittee of the Advisory Committee for Natural Resources and Energy. This committee is charged with investigating the problem of aging of nuclear power plants. It released an interim report in April and aims to produce a final report by August. Basically, it will recommend life extensions for nuclear power plants.

While NISA’s report proposes to “increase companies’ independent maintenance management capability”, there is no reason why government agencies and utilities should be exclusive players in this. Instead of relying on checks by government agencies, it should be possible to take a leaf out of Germany’s book and have an independent civilian organization carrying out independent checks. Building such a capacity would seem to be a natural response to the Mihama-3 accident, but the concept of such a ‘third party’ system of inspection seems to have been far beyond their field of vision.

Satoshi Fujino (CNIC)